Torque (Monitor) / Angle (Control)

This strategy guides the operator in reaching the desired target angle while monitoring the torque.

Parameter | Description |

|---|---|

Required tag number | A specific number must be written in the TAG of the end fitting tool. |

Name | Name of the tightening program. |

Rundown complete torque | Torque value from which the tightening operation starts. |

Torque min | Lower torque limit. |

Torque max | Higher torque limit. |

Change bolt limit | If the torque applied reaches this limit, the message Change screw is shown on the wrench display. |

Final angle monitoring torque | Torque value from which the angle measurement starts (usually set to 50% of the Target torque). |

Angle min | Lower angle limit. |

Angle max | Higher angle limit. |

Target angle | The angle target. |

Torque units | Select the unit of measurement. |

Angle limit for rehit | If the Torque min value is reached within the specified angle, the message Joint already tightened is shown on the wrench display. |

Measure torque at | Select between Torque peak and Angle peak. |

Torque correction coefficient | When extensions are used, the wrench measurement might be compensated to show a more accurate torque value. To calculate the correction coefficient, please refer to How to calculate the Torque Correction Coefficient. When extensions are not used, Torque correction coefficient = 1. |

Angle correction | When extensions cause additional wrench bending, the wrench angle measurement can be compensated to show a more accurate angle value. When extensions are not used, Angle correction = 0. |

Batch size | Number of tightenings the batch will perform. |

Max consecutive NOK | Number of accepted consecutive NOK to have an OK result. |

End cycle time | Starts when the torque goes below the Rundown complete torque after reaching the 3rd percentage. |

Ratchet time | Starts when the torque goes below the Rundown complete torque without reaching the 3rd percentage value. This allows the operator to release the torque for a while and recharge during the tightening operation. |

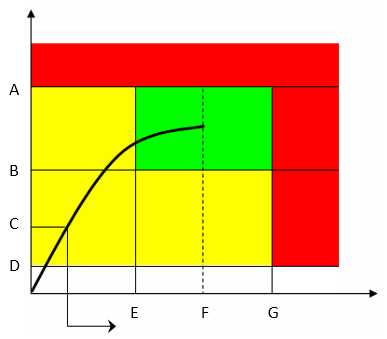

A | Torque max | B | Torque min |

C | Final angle monitoring torque | D | Rundown complete torque |

E | Angle min | F | Target angle |

G | Angle max |

The green area defines the OK result area.

During the tightening operation, LEDs, buzzer and vibration are activated as follows:

LEDs:

First radial gradient LEDs (two directions): angle over the 1st percentage (30% of the Target angle).

Second radial gradient LEDs (two directions): angle over the 2nd percentage (60% of the Target angle).

Third radial gradient LEDs (two directions): angle over the 3rd percentage (95% of the Target angle); activated also if torque/angle go over the maximum value.

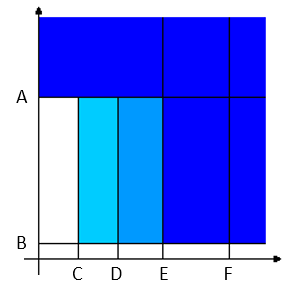

Torque vs. Angle A

Torque max

B

Rundown complete torque

C

1st percentage

D

2nd percentage

E

3rd percentage

F

Angle max

Buzzer:

The beep starts when the torque goes over the Rundown complete torque value; the signal increases when the 1st percentage, the 2nd percentage, the 3rd percentage, and the Torque max are reached.

Vibration:

Starts together with the third radial gradient LEDs.

Torque/angle results:

If the torque/angle does not exceed the torque/angle limits, the result is taken at the Torque peak or Angle peak (as specified in the tightening program).

If the torque/angle goes over the limit, the result is taken as follows:

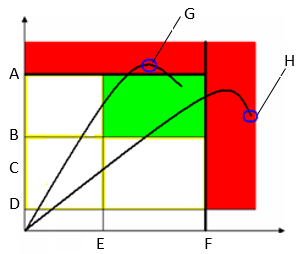

Torque vs. Angle A

Torque max

B

Torque min

C

Final angle monitoring torque

D

Rundown complete torque

E

Angle min

F

Angle max

G

When the Measure torque at is set to Torque peak, and the torque (or both torque and angle) goes over the limits, the result is taken at the torque peak.

H

When the Measure torque at is set to Torque peak, and only the angle goes over the limits, the result is taken at the angle peak.

Torque vs. Angle A

Torque max

B

Torque min

C

Final angle monitoring torque

D

Rundown complete torque

E

Angle min

F

Angle max

G

When the Measure torque at is set to Angle peak, and the angle (or both torque and angle) goes over the limits, the result is taken at the angle peak.

H

When the Measure torque at is set to Angle peak, and only the torque goes over the limits, the result is taken at the torque peak.

At the end of the tightening operation, LEDs, buzzer and vibration are activated as follows:

LEDs:

Blue LEDs: torque result between Rundown complete torque and Torque min, or torque between Torque min and Torque max but angle below the Angle min.

Green LEDs: angle and torque results within the minimum and maximum limits.

Red LEDs: angle result over Angle max, or torque result over Torque max.

Buzzer

Two beeps indicate the end of the operation; if the final result is in the red area, the signal is continuous.

To stop the buzzer, start a new tightening operation or press a button on the tool controller.

Vibration:

Stays active until the torque applied is released.