Assembling the planetary gear and the motor

Required tools

Allen keys or bits 4-10 mm

Screw bits and sockets

Torx® keys or bits T6-T25

Torque wrench

Lifting device

Screwdrivers

Pliers

Bearing puller (optional)

Feeler gauge

Lubricant | Description |

|---|---|

Klüberlub® BE 71-501 | http://www.klueber.com/en/product-detail/id/404/ |

Required spare parts

Sun gear bearing

Planetary gear

Sun gear

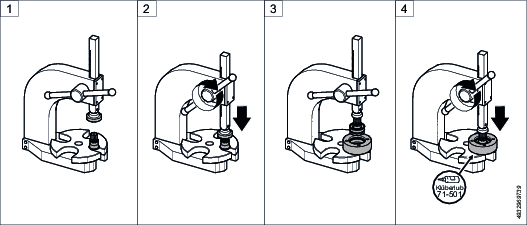

Assemble the sun gear bearing onto the sun gear axis using a press (only applicable in PST 35, PST50 and PST100), frame 1-2.

Only push on the inner ring of the bearing using the press.

Assemble the sun gear and bearing into the gear housing using a press (only applicable in PST 35, PST50 and PST100), frame 3-4.

Only push on the outer ring of the bearing using the press.

Apply a thin layer of grease (Klüberlub® BE 71-501).

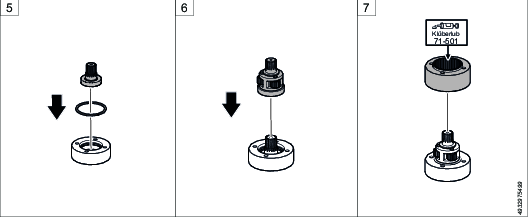

Assemble the circlip in gear housing using a pliers (only applicable in PST 35, PST50 and PST100), frame 5.

Assemble the new planetary gear (only applicable in PST 35, PST50 and PST100), frame 6.

Assemble the gear rim (only applicable in PST 35, PST50 and PST100), frame 7.

Apply a thin layer of grease (Klüberlub® BE 71-501) to the screw.

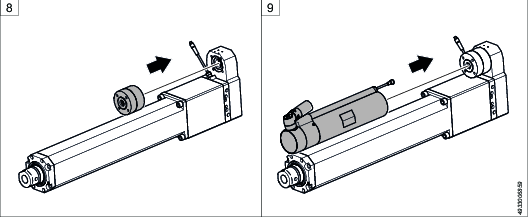

Assemble the planetary gear (only applicable in PST 35, PST50 and PST100), frame 8.

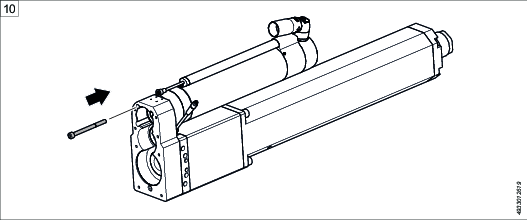

Assemble the motor, using new screws frame 9 -10.

Tighten the screws crosswise, first to 50% torque, then to 100% torque. Torque according to Installation overview.