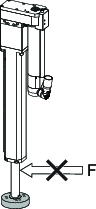

Radial force on press piston

Max allowed Press tooling weight (mass) for vertical installation

PST Press Model | With Brake (kg) | With brake (lbs) | Without brake (kg) | Without brake (lbs) |

|---|---|---|---|---|

PST5 | 25 | 55 | 8 | 17,6 |

PST10 | 50 | 110 | 8 | 17,6 |

PST20 | 100 | 220 | 16 | 35,5 |

PST35 | 175 | 385 | 28 | 61,6 |

PST50 | 250 | 550 | 40 | 88 |

PST60 | 250 | 550 | 40 | 88 |

PST100 | 500 | 1100 | 80 | 176 |

Required tools

Allen keys or bits 4-10 mm

Screw bits and sockets

Torx® keys or bits T6-T25

Torque wrench

Lifting device

Screwdrivers

Pliers

Bearing puller (optional)

Feeler gauge

Assembly

Fit a lifting eye in the rear end of the press.

Lift the press to a vertical position.

Fix the press and tighten screws diagonal to specified torque.