Adjusting the Switch Point for the Auto Trim valve

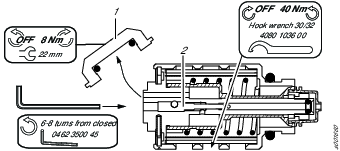

Hold the valve casing with a hook wrench and remove the cover (1) with a 22 mm wrench.

Adjust the valve (2) with a 1.5 mm Allen key. From closed (+) position to normal operation the needle valve is opened between 6 to 8 turns (-) depending on tool size.

Put the cover (1) back in position and fasten it.

Do a control of the Auto Trim valve speed.

If the valve is too much closed, the Auto Trim valve will not shift to open position when pulsing starts. If the valve is too much open, the Auto Trim will directly open to full speed and power.

Clockwise (+) rotation delays the switch point (closes the needle valve) and vice versa.

If the tool is used for reporting applications (RE) the needle valve has to be turned more open (-) to compensate for the air volume in the signal hose.