Air Pressure Monitoring, RE-Signal S1

Reporting pneumatic assembly tools provide a pneumatic signal that indicates which part of the tightening cycle the tool has reached, by means of variations in air pressure.

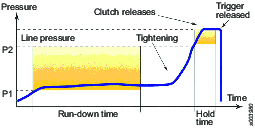

In the RE-Controller box timers are triggered when certain pressure levels are reached.

Pressure level 1 (P1) starts a timer that checks that the tightening cycle is not too short.

Pressure level 2 (P2) starts a timer that checks the time taken from when the clutch has been released to when the operator releases the trigger to ensure that it is not too short.

The controller measures the differential pressure over the motor.

It should be noted that the system does not measure torque! Regular check of installed torque/torque output of the tool must be done separately.

The RE-Controller checks the air-line pressure. One of the most common problems in air-line systems is pressure variations. If the pressure drops too much the tool might stall and/or the torque will not be correct. The RE-Controller will give a signal if the pressure drops too much.

The RE-Controller alerts the operator when it detects:

Missed fasteners

Premature tool shut-off

Stripped threads

Cross-threading

Rehits

Drop in air supply

The air pressure inside the tool is measured through a small hose (see Optional accessories - Kit RE-Signal) and converted into a digital signal. This signal is processed in the RE-Controller. The RE-Controller gives instant visual and audio feedback to the operator on whether the tightening was OK or not OK.

For further information, please see leaflet 9833 1358 01.