Changing the speed

Required tools

-

Vise

-

Allen key

-

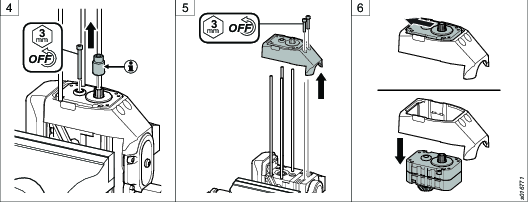

Fasten the drill in a vise with rubber pads, with the drill handle upward and the air logic unit to the left.

-

Remove the motor valve using an Allen key.

-

Pull up the motor housing and remove it.

Make sure that the motor does not fall out of the housing.

-

Loosen the gear wheel using an Allen key.

Only for a high-speed drill: Remove the spline connection.

-

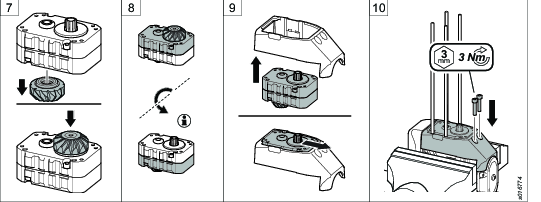

Remove the cover with the split gear inside using an Allen key.

-

Gently push the split gear forward and remove it from the cover.

-

Change position of the bevel gear to the shaft on the opposite side of the split gear.

-

Turn the split gear in a suitable position.

The markings closest to the motor housing indicate the actual speed.

-

Put the split gear back into the cover.

-

Put the cover with the split gear back into original position and tighten the cover with screws using an Allen key.

-

Tighten the gear wheel with screw using an Allen key. If you cannot install the screw easily, turn the spindle to align the splines.

Only for a high-speed drill: Put the spline connection back into position.

-

Put the motor housing back into original position.

-

Put the motor valve back into original position and secure it with screws using an Allen key.

-

Push the start button.

-

Push the emergency stop button so that it locks in position. The air supply to the motor switches off and the spindle stops.

-

Disconnect the air hose.

-

Pull the emergency stop button to reset it.

-

Reconnect the air hose.