Hydraulic Nut Installation

Preparations

Read the section Hydraulic Nut System Configuration to select appropriate hydraulic nut arrangement.

Make sure that the stud bolt threads are clean and free of damage.

Installation

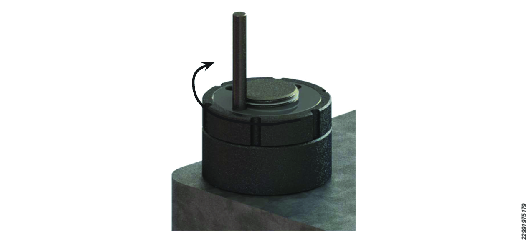

Use a tommy bar to make sure that the hydraulic nut is fully seated against the joint face.

The hydraulic nut is supplied fitted with blanking plugs in order to save space during packaging. Choose the most accessible port and remove the blanking plug.

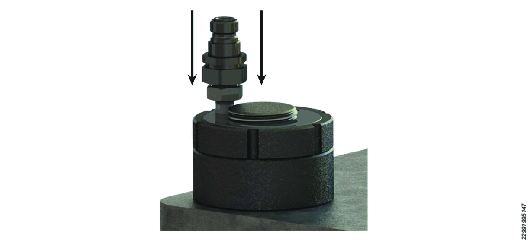

Replace the removed blanking plug with a suitable high-pressure male coupling.

Do not overtighten the connection, it can damage the male sealing cone.

Hydraulic couplers of either type should be tightened into the tool from the adaptor piece only. Required tightening torque is 25Nm

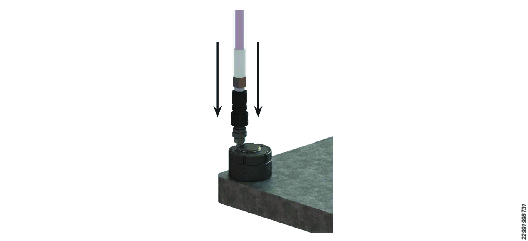

Connect the hydraulic nut to a suitable Atlas Copco pump by a length of link hose. A link hose is a length of high-pressure hydraulic hose with a male coupling at one end and a female coupling at the other.

If simultaneous tensioning of more than one bolt is to be carried out, fit one male and one female quick connect coupling to each hydraulic nut, and by using link hoses, link each nut together. The end nut on the application should have either an unconnected female coupling (to a link hose) or a blanking plug.

For pump operation, refer to the supplied pump instruction document.

Refer to the technical details that are hard stamped on the hydraulic nut.

Make sure to have knowledge about the maximum operating pressure and maximum piston movement of the hydraulic nut.

Be aware of the pressure needed to induce the required bolt load.