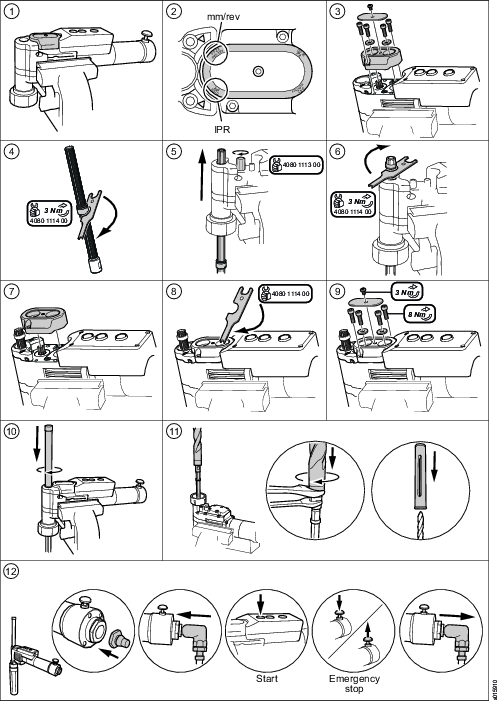

Installing the drill

Required tools

-

Vise

-

Torx wrench

-

Allen key

-

Fork-shaped tool

-

Hexagonal tool

-

Spanners

-

Fasten the drill in a vise with rubber pads, with the air logic unit upward and the drill handle to the right.

-

Note the position of the feed cassette. The markings, on the cassette end closest to the spindle, indicate the actual feed rate.

-

Remove the cassette lock, the cassette, the five screws and two washers. Use a Torx wrench on the screw of the cassette lock and allen key on the other four screws.

-

If applicable, install the starting position ring onto the spindle, and move it in position. Tighten the ring with a fork-shaped tool.

-

Install the spindle in the socket from below. Turn a hexagonal tool clockwise several turns to feed the spindle.

-

Install the depth ring onto the spindle and move it in position. Tighten the ring with the fork-shaped tool.

-

Put the feed cassette in the original position making sure that the markings on the cassette end closest to the spindle indicate the required feed rate.

-

If you cannot install the cassette easily, turn its splines with the fork-shaped tool to align them.

-

Install the washers and the four screws in the original position. Tighten the screws. Install the lock and the lock screw. Tighten the screw.

-

Put the spindle guard back in the original position and secure it.

-

Turn the drill upside-down and fasten it in the vise. Put the drill bit in the spindle. Place spanners on the spindle socket and the drill bit base to keep them from rotating and tighten the connection. Put the front part over the drill and secure it.

-

Turn the drill over and fasten it in the vise. Attach a nipple for an air hose to the connector on the drill. Connect the air hose to the nipple. Do a functional test of the emergency stop button:

-

Push the start button.

-

Push the emergency stop button so that it locks in position. The spindle must stop immediately.

-

Pull the emergency stop button to reset it. The motor must not restart.

-

Disconnect the air hose.

-