TZB25-L-AV0012-15

Air Motors

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12 months after the product is first taken into use, but will in any case expire at the latest 13 months after delivery.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

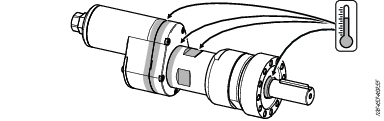

Main Components and Functions

Part: | |

|---|---|

1 | Outgoing shaft, rotating |

2 | Flange |

3 | Gear Rim, planetary gears |

4 | Casing, cylindrical gear |

5 | Turbine casing |

6 | Oil Plugs |

7 | Air Inlet |

8 | Air Outlet |

9 | Air Outlet with Silencer (Accessory) |

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

Service Overview

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Clean appropriate parts accurately

Replace any defective or worn parts

ATEX Certification Information

Temperatures

The maximum surrounding temperature for which the certification is valid is 60°C.

60°C is also the maximum allowed temperature of the compressed air when it enters the product.

If the product is installed in an equipment, the entire equipment has to correspond to the guidelines 2014/34/EU.

Make sure that the compressed air fulfil our quality demands (quality classes 2.4.3. and 3.4.4 respectively 3.5.4 acc. to ISO/DIS 8573-1:2010).

Do not exceed maximum pressure of 6.3 bar, or as stated on the product nameplate. Exceeding the operating pressure can increase the surface temperature due to higher rotating speed and the product can become an ignition source.

ATEX Code Definition

The ATEX code is: | |

|---|---|

Ex II 2 G Ex h IIC T4 Gb X Ex II 2 D Ex h IIIC T135°C Db X -20 °C ≤ Ta ≤ 60 °C | |

Description | Value | Definition |

|---|---|---|

Equipment group | II | Surface Industry |

Equipment category Group II | 2 | High level of protection

|

Atmosphere

| G | Atmosphere containing Gas, Vapors or Mist |

D | Atmosphere containing Dust | |

Safety design | h | Mechanical product |

Gas group | IIC | Hydrogene/ Acetylene |

IIB | Ethylene | |

Dust group | IIIC | Surface combustible dust |

Max surface temperature in Gas atmosphere |

| T1 = 450°C T2 = 300°C T3 = 200°C T4 = 135°C T5 = 100°C T6 = 85°C |

Max surface temperature in Dust atmosphere |

| Example temperatures: T85°C T110°C T120°C T125°C T240°C |

Special restriction, for example ambient temperature range. | X |

Ex Classification

If the product is part of an assembly where the components have different Ex classification, the component with the lowest level of safety defines the Ex classification of the complete assembly.

Explosion Prevention Guidelines

Cleanliness

-

Make sure the product is kept clean from dust and dirt to prevent increased bearing and surface temperature.

-

If using a silencer: Make sure a silencer with a filtering effect at the air outlet is installed to prevent any friction-heated particles entering into the surrounding atmosphere.

Installation

Installation Requirements

Air Quality

For optimum performance and maximum product life we recommend the use of compressed air with a maximum dew point of +10°C (50°F). We also recommend to install an Atlas Copco refrigeration type air dryer.

Use a separate air filter which removes solid particles larger than 30 microns and more than 90% of liquid water. Install the filter as close as possible to the product and prior to any other air preparation units to avoid pressure drop.

For impulse/impact tools make sure to use lubricators adjusted for these tools. Regular lubricators will add too much oil and therefore decrease the tool performance due to too much oil in the motor.

Make sure that the hose and couplings are clean and free from dust before connecting to the tool.

Both lubricated and lubrication free products will benefit from a small quantity of oil supplied from a lubricator.

Compressed Air Connection

For correct air pressure and hose size, see the Technical Product Data on - https://servaid.atlascopco.com or www.atlascopco.com.

Make sure that the hose and couplings are clean and free from dust before connecting to the tool.

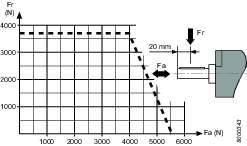

Shaft Load Diagram

Shaft Load

Make sure that the maximum shaft load is not exceeded, in order to prevent an excessive increase of the bearing temperature.

Installation Instructions

Connecting the Air Supply

When the compressed air supply is connected to the inlet, the direction of rotation will be as shown in the figure below.

Atlas Copco recommend to use the supplied fitting, Atlas Copco 4175 0738 00, and a Ø16 mm hose, Atlas Copco RUBAIR 16 or similar, to feed the motor with air. A smaller hose or fitting will restrict the airflow to the motor and cause a loss in performance.

If the exhaust air is to be piped away, a hose should be connected to the exhaust outlet.

Mounting Position

The Air motor can be installed in the positions shown in the image below.

1 | 0-90° | 2 | 0-90° |

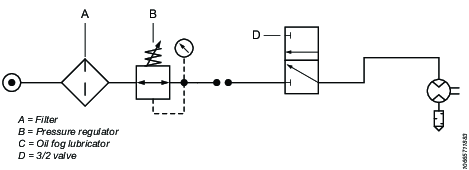

Installation Diagram

Non-Reversible motor

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines and see if you can identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the work area to your needs and the work task.

Adjust for convenient reach range by determining where parts or tools should be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by reducing the weight of the load. You can also reduce the load on the static muscles by holding the load close to the body.

Make sure to take frequent breaks.

Avoid extreme arm or wrist postures, particularly for operations requiring a degree of force.

Adjust for convenient field of vision by minimizing movement of the eyes and head during the work task.

Use the appropriate lighting for the work task.

Use ear protection equipment in noisy environments.

Use dust extraction system or mouth protection mask in dusty environments.

Operating Instructions

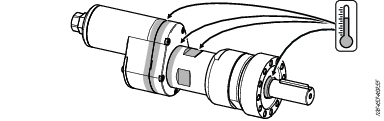

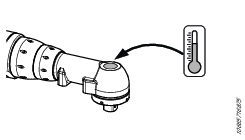

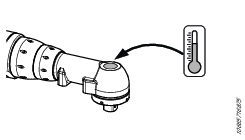

Hot Spots

The following hotspots on the motor (as seen in the figure) can reach high temperatures during operation:

Seal ring at the output shaft

Joint between front part and gear ring

Key grip

Service

Maintenance Instructions

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Clean appropriate parts accurately

Replace any defective or worn parts

Maintenance

Maintenance and repairs of this ATEX product must be carried out exclusively by authorised personnel, after which a no-load test and temperature measurements of hotspots (as seen in the figure) must be carried out and recorded in a report.

After a 5 min no-load test the surface temperature must not exceed the sum of 75°C + surrounding temperature, where the surrounding temperature can vary between -20°C to +60°C.

Preventive Maintenance

The gearbox in the TZB25 consists of two parts. The first Gear Stage is lubricated with oil. The Planetary Gear Stage, which consists of 2 to 3 planetary gears, are lubricated with grease.

| 200 hours: | 2000 hours: | Every 2000 hours: |

First Gear Stage | Check oil. | Check oil. | Check oil. |

Planetary Gear Stage | No maintenance. | Clean and inspect planetary gearbox. | Clean and inspect planetary gearbox. |

Lubrication Instructions

Rust Protection and Cleaning

Water in the compressed air can cause rust. To prevent rust we strongly recommend to install an air dryer.

Water and particles can cause sticking of vanes and valves. This can be prevented by installing an air filter close to the product to avoid pressure drop.

Before longer stand stills always protect your tool by adding a few drops of oil into the air inlet. Run the tool for 5–10 seconds and absorb any access oil at the air outlet in a cloth.

Grease Guide

Brand | Purpose |

|---|---|

Atlas Copco Turbine Gearbox oil 32 | First gear stage |

Mereta 32 | First gear stage |

Brand | General purpose, Bearings and Gears |

|---|---|

Mobile Polyrex 222 | Gears, Bearings, and seal rings |

Changing the Oil

For information about approved oils and grease see the Grease Guide.

Unscrew the two oil plugs on the side of the aluminum housing and drain the old oil.

Using a syringe, refill 12-14 ml of oil.

Clean the oil plug magnets.

Check the O-rings.

Screw the oil plugs back on the housing.

Service and lubrication of the planetary stage gearbox should be carried out by authorized personnel.

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Instruction

Part: | Recycle as: | |

|---|---|---|

1 | Screw cap | Metal, steel |

2 | Turbine casing | Metal, aluminum |

3 | Central gear wheel with bearings | Metal, steel |

4 | Front casing | Metal, aluminum |

5 | Oil plug | Metal, steel |

6 | Screws | Metal, steel |

7 | Front gear assembly | Metal, steel |