AB3-S

Tensioner

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire in 12+1 months after dispatch from Atlas Copco's Distribution Center.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tool maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are performed only in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state-of-the-art preventive maintenance through its ToolCover contracts. For further information, contact your local Service representative.

For electrical motors:

Warranty will apply, only when the electric motor has not been opened.

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: https://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

Technical Data

Max Working Pressure | 1500 bar, 21750 psi |

Max Load Capacity | 810.93 kN, 81.39 ton |

Hydraulic Pressure Area | 5406.21 mm2, 8.38 in2 |

Stroke | 10 mm, 0.394 in |

Name and Thread Size (Metric) | Prod. No. | Weight (kg) | Weight (lb) |

|---|---|---|---|

AB3-S M36x4 Tensioner | 8434244416 | 11.6 | 25.6 |

AB3-S M39x4 Tensioner | 8434244417 | 11.5 | 25.1 |

AB3-S M42x4.5 Tensioner | 8434244418 | 11.2 | 24.7 |

AB3-S M45x4.5 Tensioner | 8434244419 | 11.2 | 24.7 |

AB3-S M48x5 Tensioner | 8434244420 | 11.1 | 24.5 |

AB3-S M52x5 Tensioner | 8434244421 | 11 | 24.2 |

Name and Thread Size (Imperial) | Prod. No. | Weight (kg) | Weight (lb) |

|---|---|---|---|

AB3-S 1.1/2"-8UN Tensioner | 8434244422 | 11.4 | 25.1 |

AB3-S 1.5/8"-8UN Tensioner | 8434244423 | 11.2 | 24.7 |

AB3-S 1.3/4"-8UN Tensioner | 8434244424 | 11.1 | 24.5 |

AB3-S 1.7/8"-8UN Tensioner | 8434244425 | 11 | 24.2 |

AB3-S 2"-8UN Tensioner | 8434244426 | 11 | 24.2 |

Tensioner AB3-S Loadcell

Name | Prod. No. | Weight (kg) | Weight (lb) |

AB3-S LOADCELL C/W FITTINGS | 8434244412 | 6.9 | 15.2 |

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

If the Technical Product Data is not available on either website, please contact the local Atlas Copco Customer Center for assistance.

Tensioner Conversion Kit

Thread Size | Part No |

|---|---|

M36 × 4 | 4222912713 |

M39 × 4 | 4222912714 |

M42 × 4.5 | 4222912715 |

M45 × 4.5 | 4222912716 |

M48 × 5 | 4222912717 |

M52 × 5 | 4222912718 |

1.1/2"- 8UN | 4222912719 |

1.5/8"- 8UN | 4222912720 |

1.3/4"- 8UN | 4222912721 |

1.7/8"- 8UN | 4222912722 |

2"- 8UN | 4222912723 |

Installation

Installation Requirements

Pre-procedure Checks

Check that each bolt to be tensioned is visually free from obvious thread defects. Make sure all nuts and thread inserts are free to rotate on the bolts. Try a thread insert on a bolt and make sure they are correct mating threads.

Ensure there is sufficient stud protruding from the top of the nuts. A minimum of 1 x stud diameter is essential and also a minimum of 2 x D from top of the bolt to the base of the nut.

Also make sure full thread engagement is available through the hexagon nut on the opposite end of the studs being tensioned.

Check that all calculations pertaining to the tensioning procedure, including pressures, bolt loads, etc are available and have been reviewed by a qualified engineer with bolting experience.

Ensure that personnel are fully trained in bolt tensioning procedures and have thoroughly read this guide and safety notes.

Ensure Airbac-S tools are charged prior to use – Re-charge at the start of each shift

Ensure the pump reservoir is filled and an adequate oil volume is available.

Ensure the correct and preferred grade of oil is used in the pump. Refer to the applicable pump PI document. If the incorrect grade of oil is used, the life and performance of the system will deteriorate.

Be sure all personnel are aware of the maximum working pressure and maximum piston stroke of the tensioners. These details are hard stamped on the tensioner bodies.

Initial Configuration

Tensioner System Configuration

The most efficient use of bolt tensioning tools is where every bolt (100% bolt to tensioner ratio) is tensioned simultaneously. Tensioners can be fitted to either one side or both sides of the bolted joint depending on accessibility.

Common examples of system configuration are 100% & 50% bolt to tensioner ratio.

This manual details both of these tensioner system configurations.

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines to identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the workstation area to your needs and the work task.

Adjust for a convenient reach range by determining where parts and tools need to be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by lowering the weight of the tool, using for example torque arms, hose reels or weight balancers. You can also reduce the load on the static muscles by holding the tool close to the body.

Take frequent breaks.

Avoid extreme arm or wrist postures, particularly during operations requiring a degree of force.

Adjust for a convenient field of vision that requires minimal eye and head movements.

Use appropriate lighting for the work task.

Select the appropriate tool for the work task.

In noisy environments, use ear protection equipment.

Use high-quality inserted tools and consumables to minimize exposure to excessive levels of vibration.

Configuration Instructions

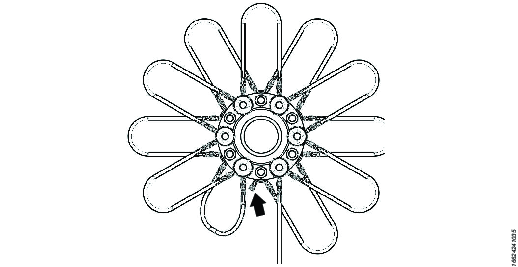

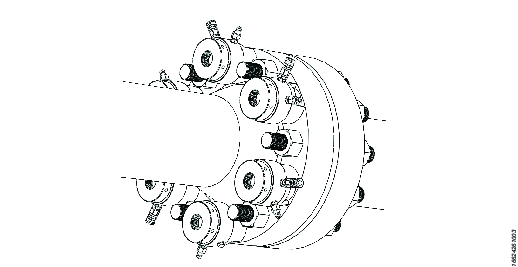

Tensioner Arrangement – 100% Configuration

All bolts simultaneously tensioned.

Commonly, due to space restrictions, it will not be possible to fit tensioners to every bolt from the same side of the bolted joint. It is normal practice to stagger the tensioners over both sides of the bolted joint.

It is normal practice to fit the bolts so adequate thread protrudes from the side of the joint that the tensioner will be fitted.

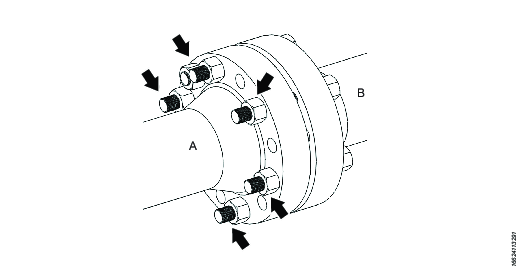

Tensioner Arrangement – 50% Configuration

Every other bolt simultaneously tensioned.

In this configuration the bolt to tensioner ratio is 50%. The tensioning procedure consists of:

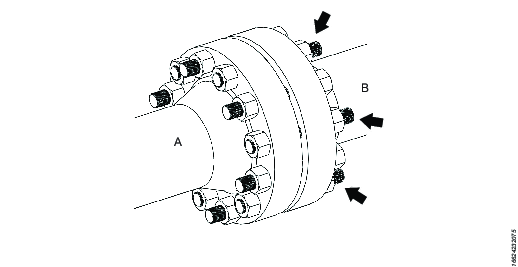

Simultaneously tensioning every other bolt, to first pass pressure “A”

Tension the final 50% of the bolts, to 2nd pass pressure “B”

Optional checking pass.

Operating Instructions

Tensioning Preparation

Make sure the tensioning team have read and understood the applicable "Airbac-S Safety Information" document.

Tensioner Installation

Prior to installing the tensioners see also Pre-procedure Checks to determine the suitable tensioner arrangement to be used.

Prior to installing the tensioners ensure the bolt threads are clean and free of damage.

Fit the nut socket over the hexagon nut.

Fit the tensioner over the stud until it sits flat on the bolted joint. Ensure the bridge access window faces radially out with easy accessibility to the tommy holes in the nut socket. Ensure the hydraulic connections are also facing radially outwards.

Place the thread insert into the tensioner bore until contact is made with the top face of the bolt. Using the tommy bar rotate the thread insert downwards until the thread insert head makes contact with the top face of the tensioner piston.

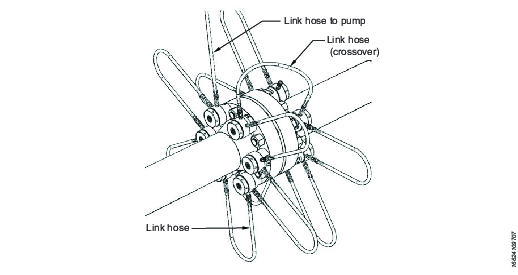

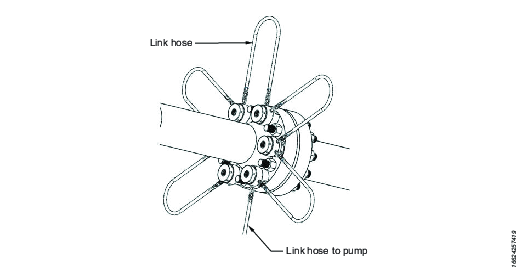

Ensure the pump pressure release valve is fully open and the pump is off. Connect the link hoses to the installed tensioners. See also configuration instructions for different tensioning procedure configurations and illustrations.

Charging Airbac-S Tool

To apply the residual air pressure to the Airbac-S tools, Atlas Copco bolting solutions have developed two separate charging systems, mounted to the hydraulic pump unit. The first system comprises of a new hydraulic pump unit (based on the D500 / D600 pump units), with a unique charging valve.

The second system is for customers with standard D500 / D600 hydraulic pump units, where a separate module can be added / retro fitted Instructions on how to attach this separate module have been produced and included in the charging module documentation 8434243874 (HTT.19030.000A).

Whichever system is used to charge the Airbac-S tools (i.e. new standalone pump unit or retro fit module), the procedure is the same.

Before connecting the main air supply to the hydraulic pump unit, make sure the 3-way valve is in the closed position.

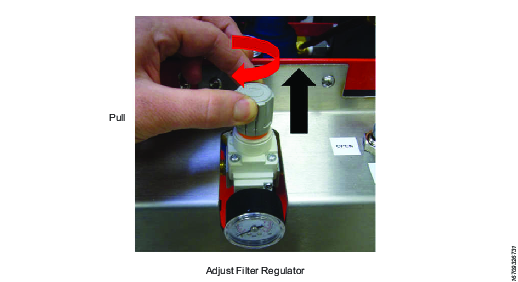

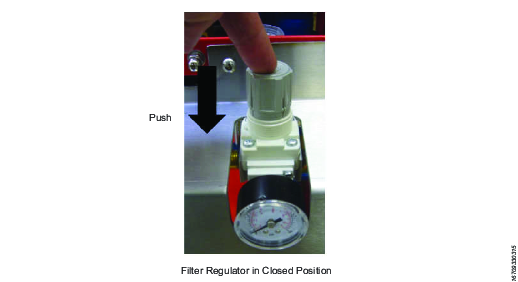

Connect the main air supply to the hydraulic pump unit. Regulate the Airbac-S charging pressure to 4.5 bar, by adjusting the small filter regulator. Make sure the adjustment cap is in the up position and rotate in a clockwise direction to increase the air pressure to 4.5 bar. To decrease the pressure, rotate in an anti-clockwise direction. When the target / required air charging pressure (i.e. 4.5 bar) has been reached, simply ‘push’ the adjustment cap down into the closed position.

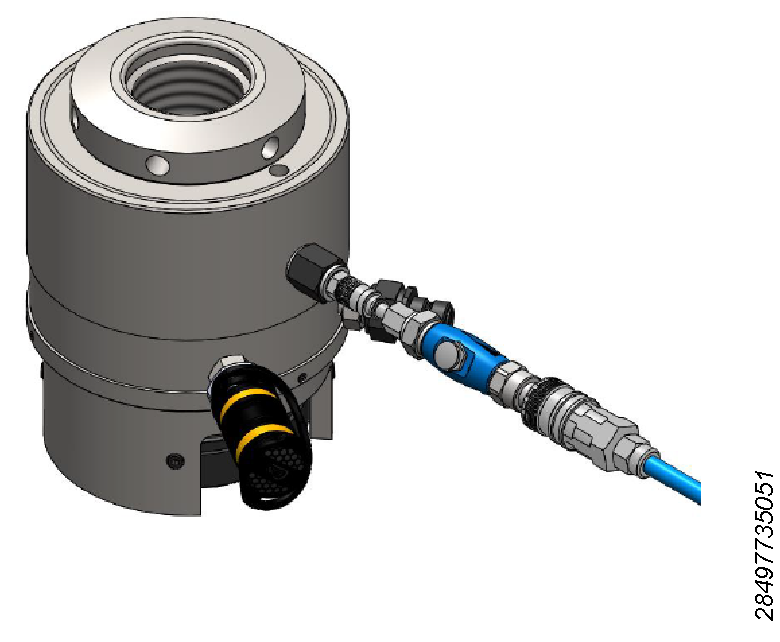

Connect the selected air-gun assembly to the air charging hose. Ensure a strong connection is made by pulling slightly on the air-gun and air-line.

Connect the Air-Nipple into the air-coupling on the tensioner. Ensure a strong connection is made by pulling slightly on the air-nipple.

Connect the nipple end of the air-line onto the coupling on the hydraulic pump unit. Ensure a strong connection is made by pulling slightly on the air-line near the nipple.

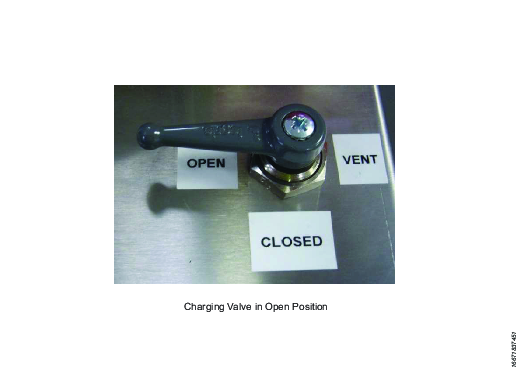

Open the air charging valve to the ‘Open’ position, this will allow the air to pass through to the air-gun assembly.

Press the button on the air-gun assembly, this will fill the Airbac-S compressed air chamber to the required 4.5 bar pressure.

When the air pressure in the Airbac-S tool has stabilized (leave for a minimum of 10 seconds), release the button on the Air-Gun assembly and move the handle on the air charging valve to the ‘Close’ position.

To remove the Air-Line from the Tensioner, turn the charging valve to the closed position and disconnect the Air-Nipple from the air-coupling by pulling back and holding the collar on the air-coupling. There will be a slight release of residual air. The operator will hear a venting sound.

The Airbac-S tool is fully charged.

Operating Airbac-S Tensioners

A red line machined into the circumference of the piston indicates the tensioner maximum allowable stroke.

Continually monitor the piston stroke during the tensioner pressurisation.

If the maximum piston stroke indicator becomes visible on any of the tensioners before the target pressure is reached immediately stop the pump, tighten the nuts down and then release the pressure to zero.

Rotate the thread inserts until the pistons are shut down into the zero stroke position.

Recommence the tensioning procedure.

Tensioner Operating Procedure

(Contact Atlas Copco if further assistance is required).

Pressurize the system initially to 70 barg (1000 Lb/in²) and check the pressure gauge on the hydraulic pump unit to ensure the pressure is steady.

If the pressure drops, release system hydraulic pressure to zero and investigate for leaks.

While the system is at zero pressure, tighten any leaking connections.

All investigation, maintenance, or leak repair work must be carried out when the tensioning system is at zero pressure.

Re-pressurize the system to 70 bars (1000 Lb/in²) and when the pressure is steady with no leaks in the system, continue to pressurize the system up to the required hydraulic pressure.

Continually monitor the tensioner for piston over-stroke as indicated by the appearance of the red stroke indicator.

If the red stroke indicator appears before the required hydraulic pressure has been achieved, go to step (9) and (10), then re-commence the tensioning procedure.

When the required hydraulic pressure is achieved, stop the pump, maintaining the system pressure.

Check the pressure gauge on the hydraulic pump unit to ensure the pressure is holding steady.

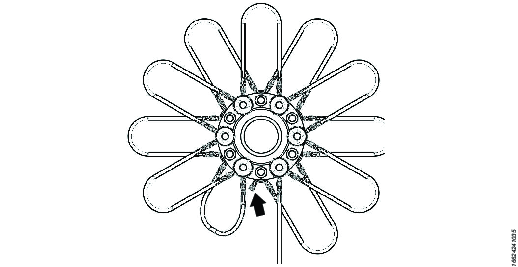

When the hydraulic pressure is steady, approach the tensioners and insert the round bar provided into the holes in the nut socket (if used) or nut.

Use the round bar to rotate the nut down onto the joint face. Ensure that the nut is fully seated on the joint face.

Apply force to the round bar to ensure the nut is firmly seated.

Release system hydraulic pressure to zero.

If the pistons are close to their fully extended position, the Airbac-S system will push the pistons to the zero-stroke position, when the hydraulic pressure has been released.

If assistance is required to return the piston use a tommy bar inserted into the thread inserts and wind the pistons down to their zero-stroke position.

Removing the Tensioner

Disconnect hydraulic hose.

Loosen the insert component from the bolt.

Insert the round bar provided into the holes in the insert to assist with rotation if required.

Lift the tensioner over the bolt and away from the application.

Remove the nut socket from the nut (if used).

Service

Maintenance Instructions

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Clean appropriate parts accurately

Replace any defective or worn parts

Lubrication Instructions

Tool Storage and Preservation

Atlas Copco standard Airbac-S tensioner are chemically blackened to provide corrosion protection.

Tools which have been exposed to water during usage (from rain or similar) should be thoroughly dried before storage. Once packed, all accessible surfaces of the tools will be sprayed with suitable non-drying rust prohibitive oil (for example, shell ensis fluid or castrol rustilo DW300X). This is to make sure that the tools remain rust free through their service life.

Pack the tools into the crate with suitable packaging material to contain them. The standard packing crates that Atlas Copco provide are not water tight and should be covered (under a waterproof tarpaulin or plastic sheeting, for example) if used for longer term storage. The standard packing crates will protect against accidental splashes but are not designed for constant wet conditions.

General Maintenance

Tools should be routinely inspected for any signs of corrosion. It is recommended that tools that have the evidence should be returned to the nearest Atlas Copco service location for refurbishment..

Lifting eyes and straps on tools should be checked before usage for any cracks, tears or any other visible damage. Lifting straps or eyebolts, which are found to be damaged, should not be used.

During storage, it is recommended that all hydraulic fittings have their connected dust caps correctly fitted to prevent any foreign objects getting into the fittings and fouling them.

Tensioners should not be dropped or hit by other hand tools as this risks causing damage to the sealing surfaces of the tool, which can result in tool failure during usage.

The tool coating must be routinely inspected and checked for any evidence of cracking or flaking. It is recommended that tools that have evidence of flaking or cracking be returned to Atlas Copco.

If at any time you have doubts about the operational suitability of a tensioner tool, please contact Atlas Copco for advice.

Atlas Copco recommend that tools are fully refurbished once every 12 months. We can provide a tool refurbishment service for a nominal cost.

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.