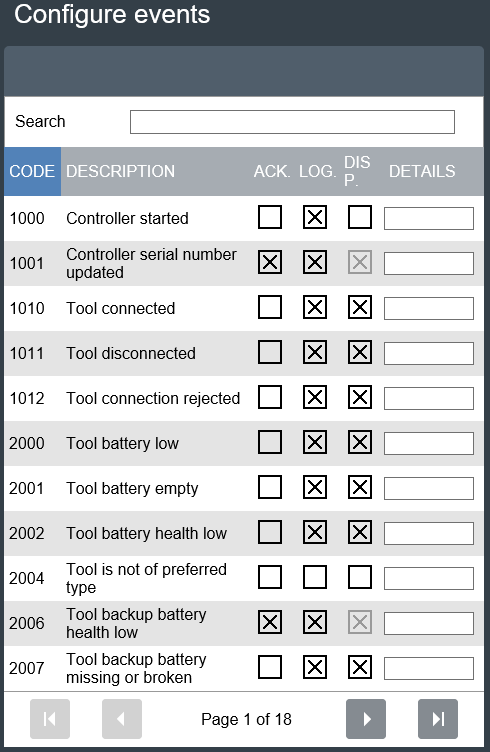

Tells the user whether it is possible to configure the event through the "Configure Event" page.

Power Focus XC (3.9)

Software

Introduction

In this section, you can find the basic information about the product and also the formatting conventions used in the topics.

Conventions

To enhance user understanding, certain formatting conventions are used throughout this document. The formatting conventions used are listed below.

Element | Notation | Description | Output |

|---|---|---|---|

General emphasis | In the Program workspace. | To make certain text elements stand out, or to highlight. | Text in Bold |

Graphical User Interface (GUI) items | Select the Function button. | Any reference to items found on screen in the GUI (for example, command buttons, icon names and field names). | Text in Bold |

Graphical User Interface (GUI) Path > | Generally, on the top of the GUI. | Navigation aid which keeps track of the location in the GUI. | For example: Controller > Program > Edit |

User input | Enter a Description for the program. | Any text input by the user. | Text in Bold |

File names | Enter a File Name for the export. | Files either exported from, or imported into the system. | Text in Bold Italic |

Variable and parameter names | Enter a Name for the export. | Variable and parameter names (not values). | Text in Italic |

Variable and parameter values | Enter a VALUE for the export. | Variable and parameter values. | Text in BOLD CAPS |

System output | Client.Domain.Models.ExportImportConfiguration | Any text output by the system. | Text in Monospace |

External links | Links to external sites that have information connected to the document or subject content. These could include:

| Selectable text to external sites | |

Internal documentation links |

If available, these links will be presented below the text. | Selectable text to internal content |

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Liabilities and Warnings

Liability

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require you to check the installed torque and rotational direction after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

Ensure that the joint conditions have not changed due to events of influence.

Be done after initial installation, maintenance or repair of the equipment.

Occur at least once per shift or at another suitable frequency.

Warnings

About the User Guide

The User Guide describes how to set up and configure the Power Focus XCPower Focus XC.

It is intended for anyone operating or servicing the Power Focus XCPower Focus XC.

Revision History

Release Number | Revision Date | Revision Description |

|---|---|---|

item | item | none |

3.9 | 01/2023 | |

3.8 | 06/2022 |

|

3.7 | 01/2022 | NEW content:

UPDATED content:

|

3.6 | 06/2021 | First official release of the user guide for Power Focus XC. |

Prerequisites

Anyone interested in learning more about Power Focus XCPower Focus XC can benefit from reading this User Guide.

For a complete understanding of the technical aspects described in the User Guide, we recommend the following:

Knowledge about tightening techniques

Experience of working with the previous versions of Power Focus

System Overview

Software Structure

Menu Overview

The controller has several menus to perform the following:

configure tightenings and hardware accessories

perform tool maintenance

administer software

view reports.

The menus available differ between the full web GUI and the simplified mobile GUI.

Web GUI

Tightening Tab

The Tightening tab lists the Tightening programs stored on the controller that are available for an individual tightening. Tightening configurations are described in the Tightening tab.

Batch Sequence Tab

The Batch sequence tab lists the batch sequences stored in the controller.

A batch sequence consists of one or more repetitive tightening programs in various combinations. Batch sequences are created and configured in the Batch sequence tab.

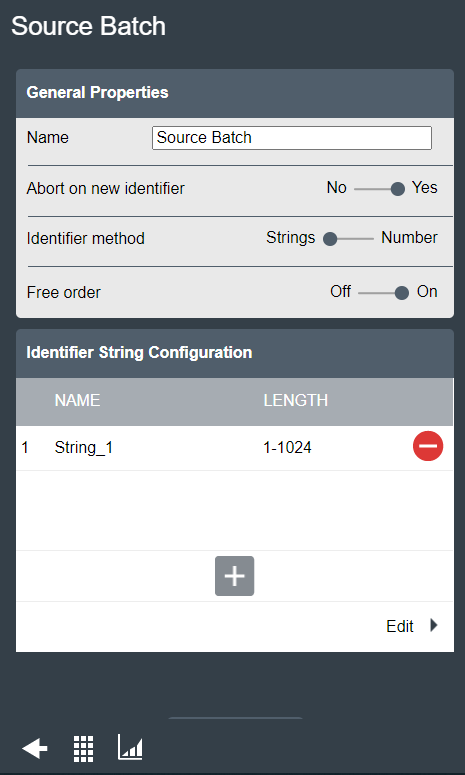

Sources Tab

The Sources tab lists the available options for controlling the selection of a tightening program, for example, a tightening program or a batch sequence, via digital input from different hardware. Scanner configurations are done in the Sources tab.

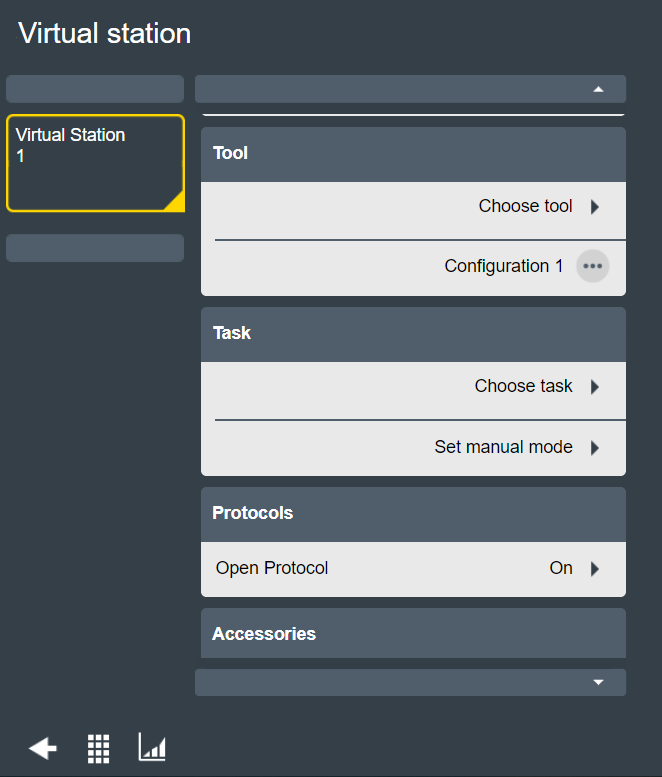

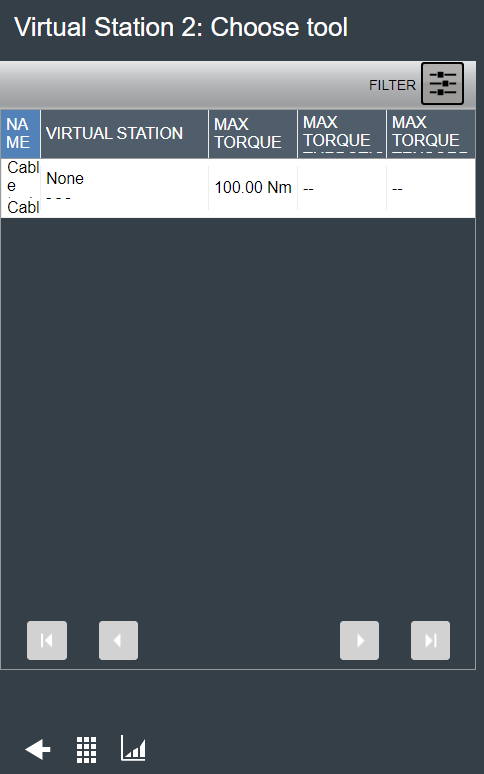

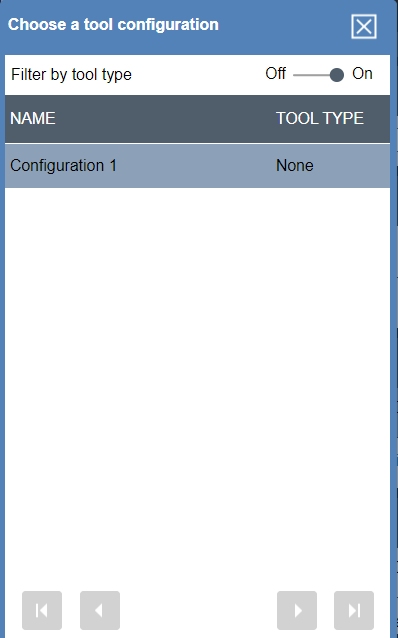

Virtual Station Tab

The Virtual station tab configures the Virtual Stations.

The Virtual Station is a software abstraction of a controller system. In the Virtual station tab the different resources, accessories, tools and tasks are assigned to a Virtual Station.

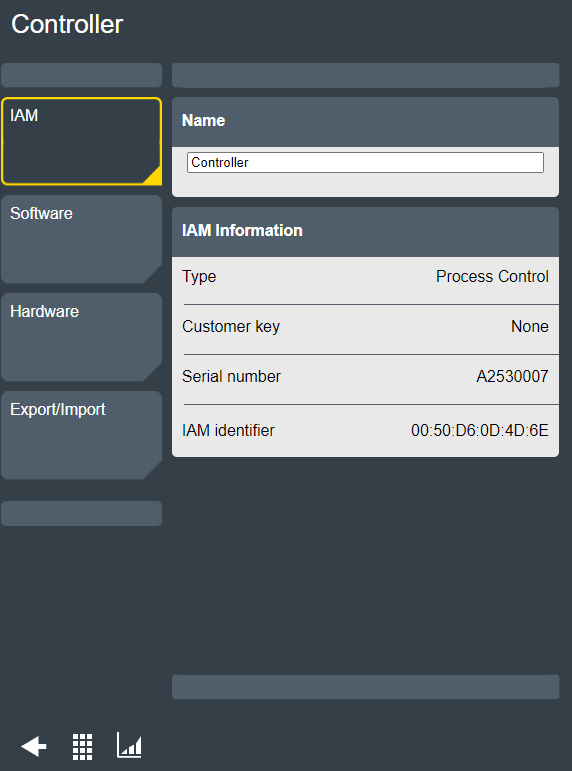

Controller Tab

The Controller tab lists hardware and software components.

The software versions stored and used in the controller are listed and can be updated. The license manager for additional features is handled. It is also possible to import or export settings to and from the controller.

Configurations Tab

A list of accessory configurations is given in the Configurations tab.

Accessories like tool accessories and socket selectors can be configured. Digital I/O signals are mapped to buttons, lamps, switches and connectors.

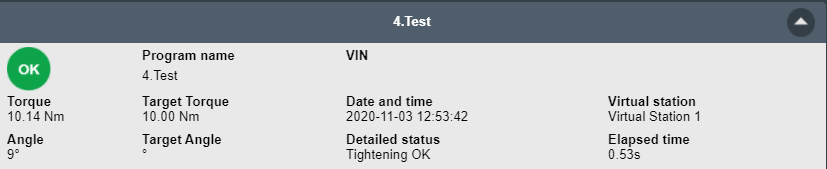

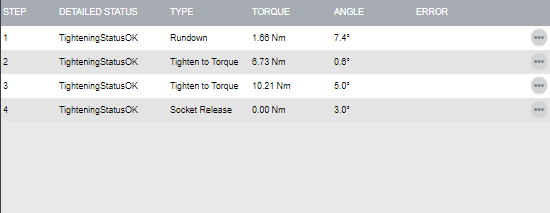

Reports Tab

In the Reports tab the tightening results and events are listed.

Settings Tab

The Settings tab is used to set up the controller specific settings, such as language, events and wireless network.

License Assignment Tab

The License assignment tab is used to assign licenses and license features to virtual stations.

Help Tab

The Help tab contains useful help sections about the controller. It is possible to download PDF files in different languages through a computer connected to the controller.

Mobile GUI

Task Tab

The Task tab lists the tightening programs stored on the controller that are available for an individual tightening. Tightening configurations are described in the Task tab.

Controller Tab

The Controller tab lists hardware and software components.

The software versions stored and used in the controller are listed and can be updated. The license manager for additional features is handled. It is also possible to import or export settings to and from the controller.

Results Tab

In the Results tab the tightening results and events are listed.

Help Tab

The Help tab contains useful help sections about the controller. It is possible to download PDF files in different languages through a computer connected to the controller.

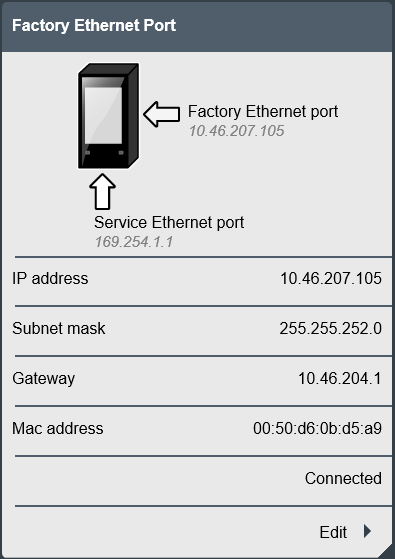

Operating and Handling

The Power Focus XCPower Focus XC is set up and configured by using a web GUI by browsing to the controller’s IP address on a connected PC. It is also possible to access the controller interface through a mobile GUI.

Web GUI

GUI Buttons and Icons

Button | Name | Description |

|---|---|---|

Add | Add an additional item. | |

Remove | Remove an item. | |

| Ellipsis | Edit an item. |

Go back | Return to previous view. | |

Scroll up Scroll down | Move in a list that is too long for the screen. | |

Maximize Minimize | Maximize or minimize a section with parameters. | |

Back (to the start) (in a list) Back (in a list) | Move back in pages of a list. | |

Forward (to the end) (in a list) Forward (in a list) | Move forward in pages of a list. | |

Close | Tap to close the window. | |

Notice | Sign showing that a parameter is configured wrong. | |

Filter | Tap to filter on items. | |

WARNING | Sign leading to a warning about the risk of injury. | |

| Pairing | Tap to pair a STB tool or a STwrench to the controller via WLAN or Bluetooth. |

Validate program | Tap to check if a program is valid. | |

Download manual | Tap to download a manual. | |

Go home | Go to the Home screen. | |

Go result | Go to the live results screen. |

Mobile GUI

GUI Buttons and Icons

Button | Name | Description |

|---|---|---|

Add | Add an additional item. | |

Remove | Remove an item. | |

Ellipsis | Edit an item. | |

Back | Return to previous view. | |

Maximize Minimize | Maximize or minimize a section with parameters. | |

Back (to start of list) Back (one page) | Move back in pages of a list. | |

Forward (to end of list) Forward (one page) | Move forward in pages of a list. | |

Close | Close the window. | |

Notice | Sign showing that a parameter is configured wrong. | |

Download manual | Tap to download a manual. | |

Home | Go to the Home screen. | |

Result | Go to the live results screen. | |

Protocol connection | See protocol status. |

Quick Start Guide

To provide a better overview of the system, the following instruction touches upon the steps that are required to start using the system.

The instruction does not cover all system features, but focuses on the most basic.

Web GUI

Select the type of tool to use. The tightening strategies available, depend on the type of tool you select.

Set a Tightening program that contains all relevant parameters, for example target angle and target torque. The main purpose of the tool is to perform a tightening.

Create a Virtual station and assign a tool to it. The virtual station acts as an interface between the controller and the tool, so several tools can be connected to a single physical controller. A virtual station is always required, even if only one tool is connected to the controller.

Assign a task to the Virtual station. The task can be either a tightening program, or a specified digital input (from for example a barcode scanner). The tool assigned to the station will now be able to perform the task.

Mobile GUI

Select the type of tool to use.

Create a tightening Task and set the relevant parameters, for example target torque and target angle. The main purpose of the tool is to perform a tightening.

The created task will be assigned to a virtual station. The tool assigned to the station will now be able to perform the task.

License Introduction

Licenses for controller features are managed through the Functionality Management System (FMS). This allows customers to tailor controller functions to their specific needs through a dynamic licensing scheme.

Licenses can be obtained for individual features or collections of features and can be deployed across multiple Virtual Stations. The licenses can be returned to the pool when they are no longer required. Licenses can be obtained through the Atlas Copco License Portal (ACLP). Licenses can be downloaded from the ACLP and managed/distributed through ToolsTalk, or can be stored on a FMS Portable (USB drive) to be inserted into the controller.

Note that the creation and management of a customer account in the ACLP is not covered in this documentation. Contact your local Atlas Copco representative for more information.

Licenses Overview

Configuration of features governed by licenses can be done even in the absence of an installed license. E.g. configuration of tightening programs and configuration of Multistep programs. Assigning these features to a tool or virtual station is also possible. Running the feature without a valid license, however, will require the installation of the appropriate license.

License enforcement is performed at two stages: assignment and runtime (trigger pressed). If a feature for which no license is installed is assigned to a Virtual Station, a red exclamation mark will appear at the Virtual Station View in ToolsTalk 2. The controller GUI will also show a warning triangle at the tool or task section (depending on what is missing). If a feature for which no license is installed is started (i.e. trigger pressed), an event will be presented to the user informing the user of which license is missing. It will not be possible to proceed without a correct license installed.

Running an unlicensed feature will, in most cases, result in a locked tool.

Many features and functions in the controller require a license in order to be assigned and used by a virtual station. There are three types of licenses:

Virtual Station Type

Fixed collection of features bundled together in a single package. The Virtual Station Type determines, among other things, what tools can be run, how many programs and sequences can be used, which tightening strategies are available, and the type of reporting that can be done. The features contained in each Virtual Station Type are features that often are used in conjunction with each other, or which have internal dependencies that require the presence of other features in the package. Virtual Station Types are assigned in their entirety to a virtual station. The virtual station can then make use of all features contained in the Virtual Station Type. In order to be able to perform tightenings, a Virtual Station has to be assigned a Virtual Station Type license. Depending on the license type, various tightening options will be enabled or blocked.

Virtual Station Feature

Individual features which can complement Virtual Station Types. A lot of features can be purchased as a single license.

License Sources

Licenses used on a controller can be pulled from several different sources. The number of simultaneous sources is limited to 10 (either 10 FMS Portable sources, or one License Server (TT2) in addition to 9 FMS Portable sources). If you would like to add licenses from a source when the source limit (10) has been reached, all licenses from one source need to be removed from the controller to make room for licenses from the other source.

Source Overview

The Source Overview tab (License assignment > Source Overview) provides the user with an overview of the licenses installed on the controller, as well as where they were installed from. A maximum number of 10 different sources can be displayed here, and each will be designated with FMS P (for FMS Portable, or dongle), or License Server (TT2).

Clicking on any license source will present that source's detailed license source information. It lists the source name and type, as well as the number and type of licenses in each category (Virtual Station Type, Virtual Station Feature and Controller Feature).

Supported Tools

Tools supported by a Virtual Station may vary depending on the Virtual Station type on the controller.

Supported Tools | BatchControl | JointControl | StationControl | CriticalControl | ProcessControl |

|---|---|---|---|---|---|

BCP / BCV | X | - | - | - | - |

TensorSB | - | X | X | - | - |

TensorSL | - | - | X | X | X |

TBP | - | - | X | X | X |

TensorST | - | - | X | X | X |

TensorSTR | - | - | X | X | X |

SRB | - | - | X | X | X |

TensorSTB | - | - | X | X | X |

STWrench | - | - | X | X | X |

TensorES | - | X | X | - | - |

TensorSR | - | - | X | X | X |

QST (Fixtured spindle) | - | - | X | X | X |

TBPS | - | X | X | - | - |

MWR-S (Mechatronic Wrench Signal) | - | - | - | - | - |

MWR-T (Mechatronic Wrench Torque) | X | X | X | X | - |

MWR-TA (Mechatronic Wrench Torque Angle) | - | - | X | X | X |

External tool | X | X | X | X | X |

Installation and Upgrade

In this section, you can find information to help with the initial installation of the product, or upgrading from one version to another.

License Installation

Installing Licenses on the Controller

Note that licenses sources are limited to 1 License Server (TT2) and 9 FMS Portables (dongles) simultaneously. Licenses are installed either through the server (ToolsTalk 2) or FMS Portable. If the license source limit is reached, all licenses from one source need to be removed from the controller in order to add licenses from another source.

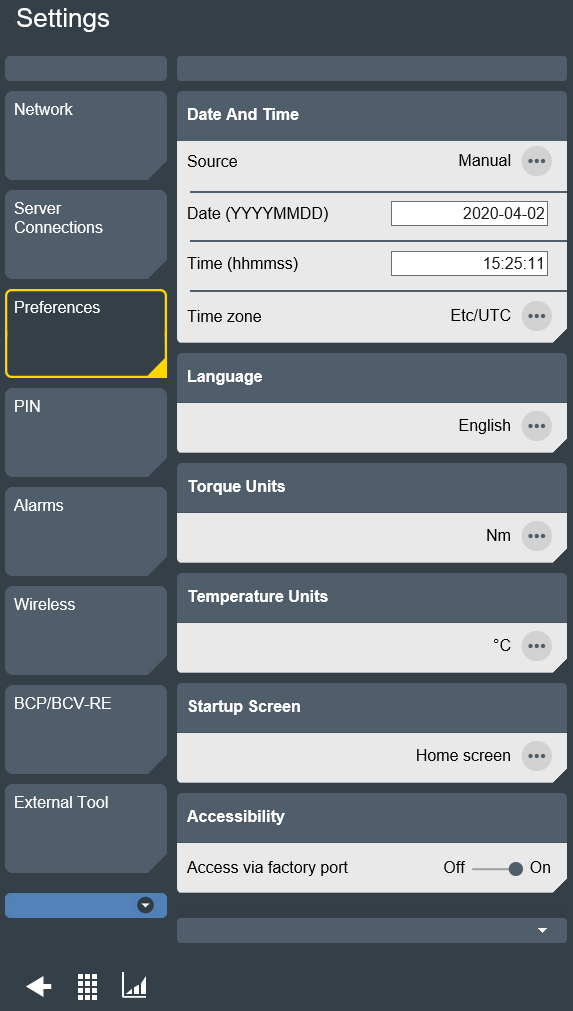

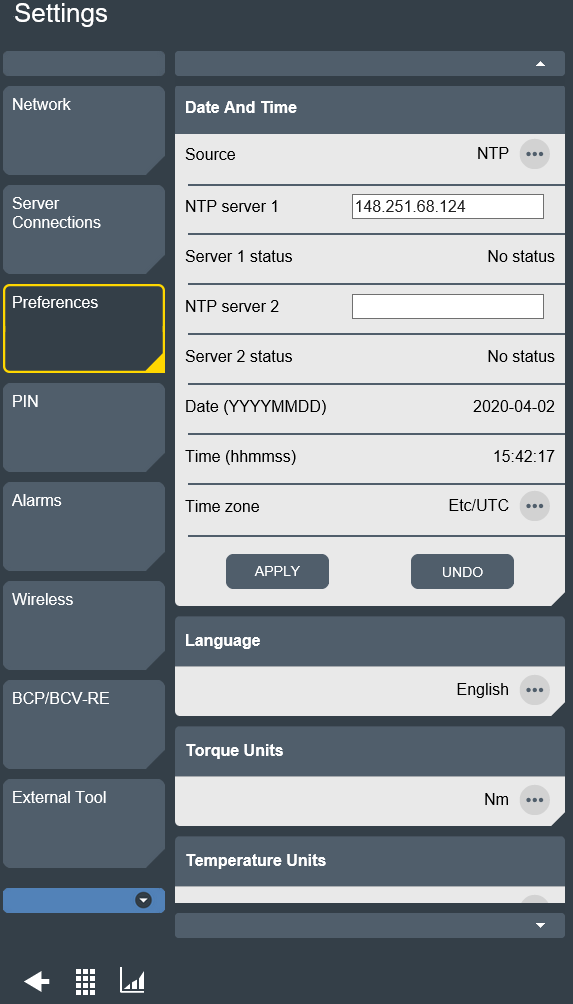

Before installing licenses through the server (ToolsTalk 2), make sure that the controller time is synced with the server time.

Installing from the Server

Distributing server-based licenses is done through ToolsTalk 2. Please refer to the ToolsTalk 2 User Guide for instructions on installing licenses.

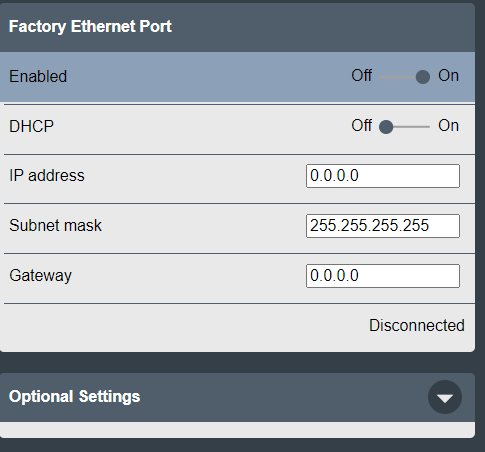

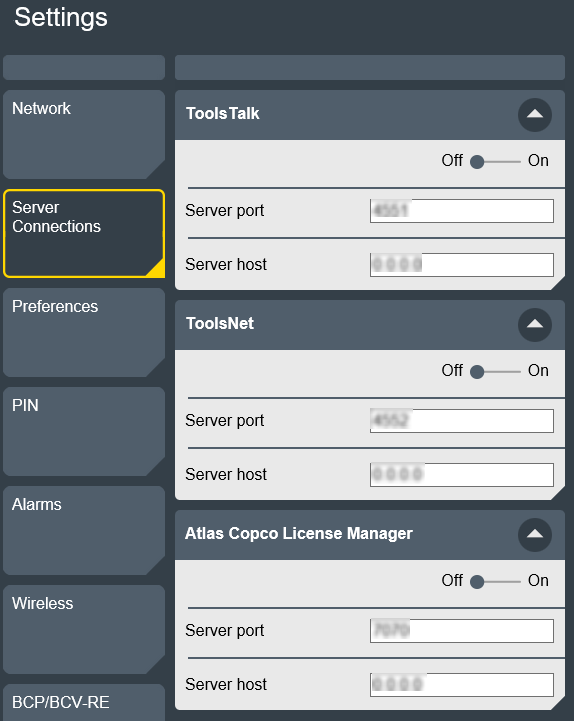

In order to be able to install licenses using ToolsTalk 2, the correct license server needs to be configured:

Select the Settings menu, and select the Server connections tab.

In the Atlas Copco License Manager field, set the switch to On.

Insert the correct Server host IP address (usually the same as the IP address for ToolsTalk 2) and Server Port.

Select Apply.

Installing from FMS Portable (USB)

The Functionality Management System (FMS) uses a special FMS Portable device to transfer functionality to and from a controller. The USB flash drive contains both a general purpose memory area and a trusted storage area that is only accessible by the License manager in a controller. The purchased feature items are downloaded from Atlas Copco to the general purpose area. The first time the FMS Portable is inserted into a controller with a License manager, the file is detected and decoded and the feature items are transferred to the trusted storage area that is only accessible from a License manager.

If you have a USB drive with the licenses installed, perform the following steps to install them on the controller.

Insert the USB into the USB port in the controller

The USB License Management window will pop up in the GUI. The Pool column will show the total license count on the controller from all sources. The Available on FMS P column shows the licenses available on this dongle, while the From this FMS P column shows the number of licenses that have been moved to this controller from this particular FMS P.

Select the left-pointing arrow next to license you want to install on the controller.

The number in the Available on FMS P column will decrease by 1 and the number in the From this FMS P column will increase by 1.

The user will be presented with events on the controller for both license transfer start and end.

Automatic License Assignment

A process control license is assigned automatically to the first created virtual station. The license is assigned if it is available on the controller and no other license is assigned to the virtual station. The automatic license assignment occurs during upstart of the controller.

License sync

Existing licenses are checked against the license server every two hours. If no response from the license server is obtained within a 14 day period, the affected licenses will be revoked. The user will also be warned when licenses are about to expire. When a license is within 7 days of expiration, the user will be presented with a warning once every two hours. If licenses are not renewed, they will expire and the affected functions will no longer be available.

Removing Licenses from the Controller

One way of removing an FMS Portable-installed licenses are described, for instructions how to remove server-installed licenses, please refer to the ToolsTalk 2 User Guide.

Removing FMS Portable-Installed Licenses

Make sure the FMS Portable is inserted into the USB port in the controller.

[If the USB License Manager window is not visible] Select the License Assignment menu.

Select the USB icon in the top right of the window.

The USB License Manager window pops up.

Select the right-pointing arrow next to the license you want to remove from the controller.

Licenses that are assigned to virtual stations can be removed from the controller. However, the Virtual Station will become unusable as a result.

Configuration

In this section, you can find detailed information about how to create, modify, and verify product settings.

Web GUI

Working with the Tightening Tab

Changes made to tightening programs in any section need to be actively applied by clicking the Apply button in the bottom right corner of the GUI. Alternatively, changes can be undone by clicking the Undo button in the same location.

When navigating away from the section where changes have been made (by using the Back, Home or Result button), the user will be presented with a warning pop-up where the changes can also be applied or undone. The user cannot proceed without applying or undoing changes.

Controller features, such as the Low Reaction Tightening Strategies and controller-wide functions among others, require licenses distributed through the Functionality Management System (FMS). Whereas configuration of features is possible without specific licenses, the assignment and use of those features will require the correct license to be installed on the controller. Please refer to Licenses (FMS) for more detailed information on licenses.

The Power Focus XCPower Focus XC tightening programs need parameters to be set in order to perform tightening. Selecting a Strategy and either the Target torque or Target angle are mandatory. Other settings are optional, such as Soft start, Selftap, and Torque compensation. It is also possible to monitor the tightening as it progresses by adding limits within which the torque, or angle the nut turns, must remain.

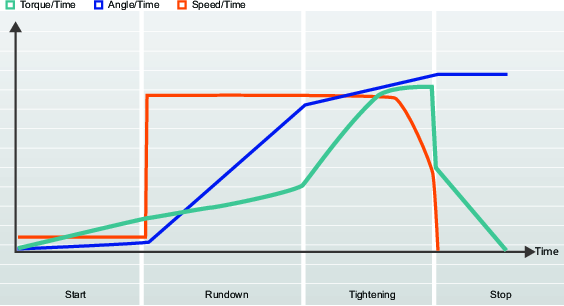

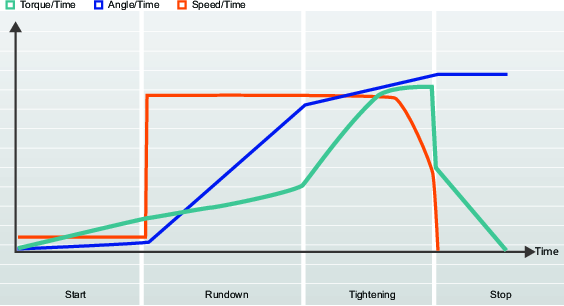

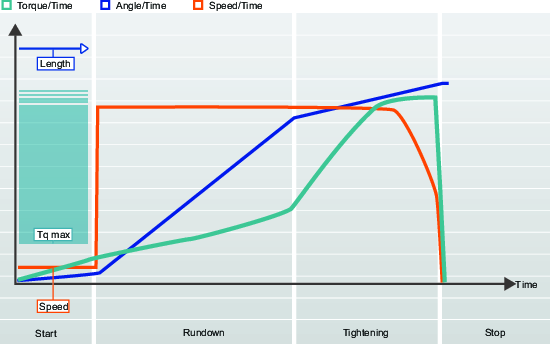

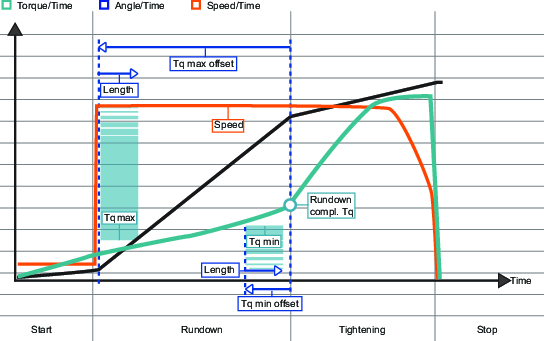

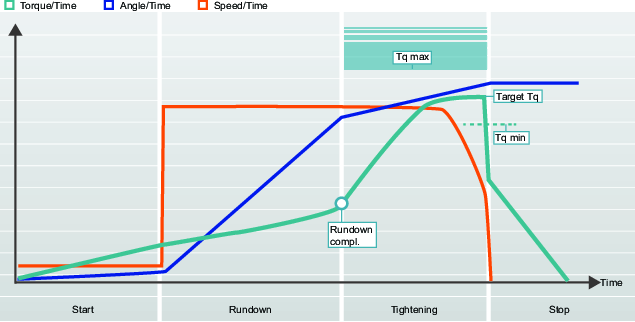

The tightening procedure is divided into four steps: Start, Rundown, Tightening and Stop.

Tightening Programs

By selecting the tightening program it is possible to choose the method for applying clamping force (or pre-load) to the joint. Different joints require different strategies for how to apply the desired clamping force and to minimize unwanted in-service effects.Power Focus XCPower Focus XC can store up to 1,000 tightening programs.

In the Web HMI, a maximum of 1,000 tightening programs can be created.

In the Mobile HMI, a maximum of 500 tightening programs can be created.

The TurboTight strategy, enables the option to use Manual programming or Quick prog - for more information, see the paragraph TurboTight.

The Quick step, Two step and Three step strategies enable the choice of tightening towards a Target torque or a Target angle value.

The External result strategy, is used when OK tightenings are indicated by an external digital signal - for more information, see the paragraph External result.

All tightening programs require that you at least set the Target torque or Target angle value.

Parameter | Description | Default value |

|---|---|---|

Strategy | Available tightening programs. TurboTight: No additional tightening behavior is used as default. Only target values are used. Quick step: Adds an initial tightening step to reduce pre-load scatter. Two step: Adds a pause between the first and final tightening step to further counteract short-term relaxation effects. Three step: Tightens to a defined First torque value, then loosens the screw and immediately retightens it to Target torque or Target angle. Wrench - production: Tightening strategy to use with an ST Wrench. Wrench - quality: Strategy used for quality test of tightenings with an ST Wrench. Rotate: Rotates the spindle a specified speed and angle. External result: presents a predetermined tightening result instead of measured torque/angle. Multistep: Tightening strategy consisting of multiple configurable steps, with restrictions and monitors. | TurboTight |

Target type | Defines the type of the target value in the final step. Target torque: The tightening aims towards the specified target value when performing the final step. Target angle: The tightening aims towards the specified target value when performing the final step. |

|

Target torque | Defines the target torque of the tightening of the final step. |

|

Target angle | Defines the target angle of the tightening of the final step. |

|

Target speed | Activates setting the tool speed for the final step manually or using the default speed. Auto: Uses a value that is calculated based on the Tool max speed. Manual: Specify the tool speed manually. | Auto |

<Manual> | Tool speed during tightening or during the final step. |

|

TurboTight

TurboTight is the default tightening strategy and it is designed to perform a very fast and ergonomic tightening based on the maximum speed of the tool (Tool max speed). This strategy has two options:

Quick prog, that requires only the Target torque to be set to perform the tightening.

Manual, that allows the user to configure several tightening parameters.

To minimize the risk of unexpected jerk at the end of the tightening when using the TurboTight tightening strategy, make sure to activate Time monitoring.

To minimize the risk of unexpected jerk at the end of the tightening when using the TurboTight tightening strategy, make sure to set the Time Max Limit.

Time Max Limit is enabled by default, but it is necessary to setup the related values. In the tightening stage, set Angle Limit to From Rundown Complete.

Set Time Max as low as possible, without stopping the normal tightening. In the rundown stage, set Rundown Complete Torque so that it is triggered when the torque start to increase.

Depending on the joint properties, for example if the joint is very stiff or very soft, a different tightening strategy than TurboTight might be needed.

TurboTight is not available for Joint Control.

Fine-Tuning the TurboTight Strategy

TurboTight tightening strategy points to the target torque, and the result can be below or above the target. The most important parameter for TurboTight tightening strategy is the speed. It is possible to keep maximum speed for most tightenings, but if all/some of the tightenings overshoot, decrease the speed in small steps. Rundown Complete Torque is not used for controlling of the tightening; it is only used for calculating of limits and results.

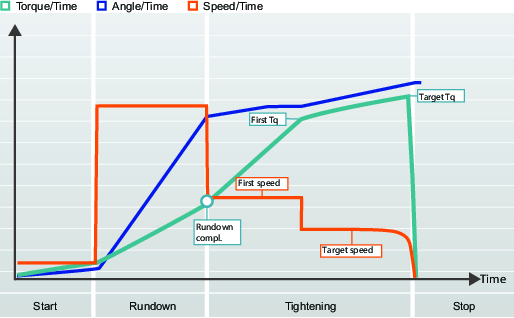

Quick Step

Quick step is a tightening strategy used to reduce the joint’s preload scatter by adding an initial step with a given torque and speed, and then reducing the target speed in the final step.

Parameter | Description | Default value |

|---|---|---|

First torque | Target torque for the first step. |

|

First torque | Torque during first step. | 80% of Target Torque |

First speed | Target speed for the first step. |

|

First speed | Tool speed during first step. | 50% of Tool max speed |

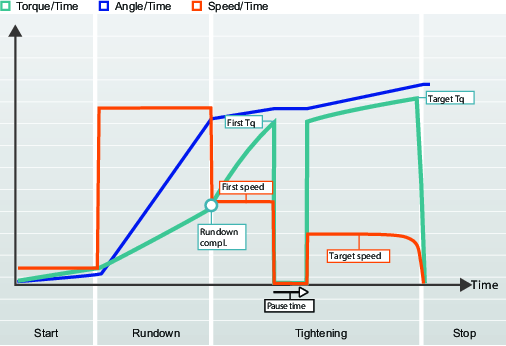

Two Step

The Two step strategy is very similar to the Quick step strategy except that it adds a small time delay between the first step and the final step, to further counteract short-term relaxation effects in the joint.

Parameter | Description | Default value |

|---|---|---|

First torque | Torque during first step. | 80% of Target Torque |

First speed | Target speed for the first step. |

|

Pause time | Time between first and second step. | 50 ms |

Fine-Tuning the Two Step Strategy

When the First target is reached, the tool makes an immediate stop for a specified time before it continues with the final step. The First torque value and the Pause time should be chosen to improve ergonomics for hand-held tools.

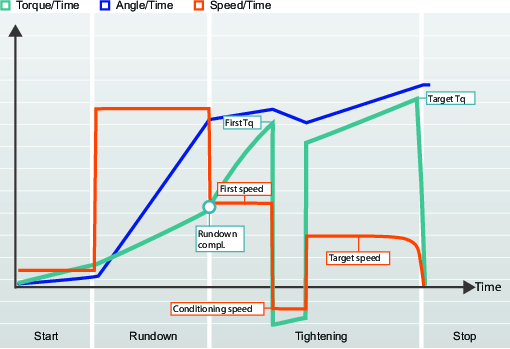

Three Step

The Three step strategy adds a loosening step between the first step and the final step, to overcome short-term relaxation effects due to embedment, and reduce preload scatter. This is sometimes used to condition the joint. This can be useful in, for example, joints with many adjoining surfaces and will have a greater effect on new parts than on reused ones, due to the smoothing of surfaces, which reduces embedment.

Conditioning the joint is done by tightening the first step to a given torque, First torque, and then releasing the load by turning the nut a specified Conditioning angle and then retightening the nut to its Target torque or Target angle.

The target torque can be lower than the torque reached during the first step after rundown. In order for the target torque to be lower than the first torque, set target torque (Tightening parameters > Tightening step > Final step > Target torque) to a value lower than First torque (Tightening parameters > Tightening step > First step > First torque).

If Angle is used as a target in the tightening program, the Target angle is measured from the position at the end of the loosening step (conditioning).

Behavior of Measure torque at, and Measure angle to

The Max torque value and Value at peak torque measured under Result evaluation for Measure torque at and Measure angle to, respectively, represent the highest values measured over the entire tightening. This means that if the Target torque is set lower than the First torque, the Result evaluation value will be higher than the end value. In order to view the tightening's final value, both Measure torque at, and Measure angle to should be set to Value at shutoff.

Parameter | Description | Default value |

|---|---|---|

First torque | Torque during first step. | 80% of Target Torque |

First speed | Tool speed during first step. | 50% of Tool max speed |

Conditioning speed | Tool speed during the conditioning step. | 50% of Tool max speed |

Conditioning angle | Angle to turn the socket during the conditioning step. | 180° |

Fine-Tuning the Three Step Strategy

When the First target is reached and the conditioning step is entered, the tool makes an immediate stop and reverse before it continues with the final step. This conditioning step may need to be fine-tuned to improve ergonomics for hand-held tools.

STwrench

The STwrench is connected to a controller using a wireless connection and is configured through the controller GUI or the web GUI.

The STwrench is configured under the tightening menu in the same way as the other tightening strategies.

The STwrench has a Rapid Backup Unit (RBU). The RBU defines the wrench function and stores the tightening programs. The controller supports currently only the RBU of the type Production.

The STwrench End-fitting tool (socket) contains a RFID TAG with a programmable number. This wrench uses this number to automatically recognize the tool and which program that can be used. The RFID TAG also stores the torque and angle correction coefficients.

The STwrench has several programs both for production tightening and for quality control.

The STwrench can only support tightening programs supported by the tool (Wrench Production and Wrench Quality).

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

STwrench Start Step Parameters

The parameters shown in the tables are available if one of the STwrench strategies are used. There are several combinations of strategies. Some of the parameters are only available for certain strategies and may not be visible in other strategies.

Parameter rules are automatically checked. If a violation occurs, the error indicator  is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

Switching between strategies can result in the error indicator being shown. This indicates that the chosen combination is invalid, and needs to be corrected.

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Tag number | On: after enabling TAG Check switch (Configurations > Tool Configuration > TAG Check > On), a correct TAG number is required to run the tightening program. Off: The TAG number is not checked. | Off | |

Required tag number | Tag number = On | The required TAG number for this tightening program. | 1 |

Rehit detection | The parameter options are: Complete or Off . | Off | |

Torque correction coefficient | In certain cases extensions may be needed to fit the application. In this case the wrench measurement must be compensated to show a correct value. For more information about to calculate the correction coefficient, see the STwrench User Guide (printed matter number 9836 4134 01). The parameter is stored in the RFID TAG in the End-fitting tool. | 1.0 | |

Angle correction | In certain cases extensions may be needed to fit the application. In this case the wrench measurement must be compensated to show a correct value. To calculate the correction coefficient, please refer to the STwrench user guide. The parameter is stored in the RFID TAG in the End-fitting tool. | 0° |

STwrench Rundown Step Parameters

The parameters shown in the tables are available if one of the STwrench strategies are used. There are several combinations of strategies. Some of the parameters are only available for certain strategies and may not be visible in other strategies.

Parameter rules are automatically checked. If a violation occurs, the error indicator  is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

Switching between strategies can result in the error indicator being shown. This indicates that the chosen combination is invalid, and needs to be corrected.

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

Rundown complete is in the STwrench documentation defined as Cycle start , this is when the tightening step begins.

Parameter name | Description | Default value |

|---|---|---|

Rundown complete torque | Definition of the Rundown complete point | Depends on the smarthead minload (usually 5% of nominal torque) in Nm |

Ratchet time | 5000 ms |

STwrench Tightening Step Parameters

The parameters shown in the tables are available if one of the STwrench strategies are used. There are several combinations of strategies. Some of the parameters are only available for certain strategies and may not be visible in other strategies.

Parameter rules are automatically checked. If a violation occurs, the error indicator  is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

Switching between strategies can result in the error indicator being shown. This indicates that the chosen combination is invalid, and needs to be corrected.

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Target | Select the target from the drop-down menu. Torque, Angle, Torque or Angle. | Torque | |

Target Torque |

| Defines the target torque for tightening step. | 0 Nm |

Target Angle | Target = Angle | Defines the target angle for tightening step. | 360° |

Torque limits | Target = Torque | Selection made by a switch. Auto or Manually position. |

|

Torque min | Torque limits = Manual | Torque value for the lower limit | 0 Nm |

Torque max | Torque limits = Manual | Torque value for the upper limit | 0 Nm |

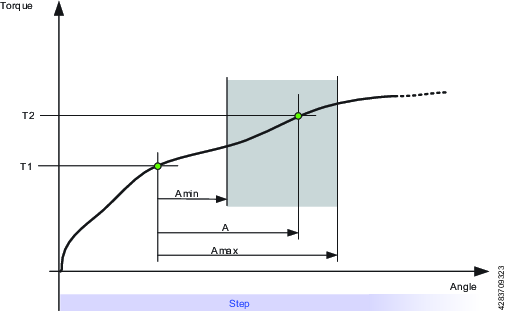

Angle limits | Target = Angle | Selected from a drop-down menu. The parameter options are: Auto or Manually. Angle values for max and min can be or selected | |

Angle limits | Target = Torque | Selected from a drop-down menu. The parameter options are: Off: No angle limit monitoring. From rundown complete: The monitoring window is set from when the Rundown complete torque is reached. From torque: The monitoring window is set from when the specific torque value is reached. | |

Final angle monitoring torque |

| Torque value from when the angle limits are monitored | 18.75 Nm |

Angle min | Angle limits = on or manually | Angle value lower limit | 324° |

Angle max | Angle limits = on or manually | Angle value upper limit | 396° |

Angle search limit | Angle limits = manually | ||

Measure torque at |

| Selected from a drop-down menu. The parameter options are: Max torque value Value at peak angle |

|

NOK on final less than target |

| Selection made by a switch. On or Off position. | Off |

Change bolt limit |

| 50 Nm |

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Torque compensation point | Torque compensation = On | 0° | |

PCT distance | Torque compensation = On | 360° | |

PVT interval | Torque compensation = On | 180° | |

Delay monitoring | Torque compensation = On | 0° | |

Torque min | Torque compensation = On | Torque value for the lower limit | 1 Nm |

Torque max | Torque compensation = On | Torque value for the upper limit | 20 Nm |

Compensation value | Torque compensation = On | Selected from a drop-down menu. The parameter options are: Average torque Peak torque |

STwrench Loosening

The parameters shown in the tables are available if one of the STwrench strategies are used. There are several combinations of strategies. Some of the parameters are only available for certain strategies and may not be visible in other strategies.

Parameter rules are automatically checked. If a violation occurs, the error indicator  is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

Switching between strategies can result in the error indicator being shown. This indicates that the chosen combination is invalid, and needs to be corrected.

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Loosening limit | If this parameter is set to a value greater than 0, Power Focus checks if a negative torque exceeding this value is applied during the tightening. In that case, the overall status of the tightening is marked as Not OK. This function is started when the wrench reaches the Cycle Start (before starting the tightening, a loosening is allowed and does not produce results). This function is used to detect unwanted loosening at the end of a tightening (for instance, when the wrench is disengaged from the joint). | 0 Nm |

STwrench Stop Step Parameters

The parameters shown in the tables are available if one of the STwrench strategies are used. There are several combinations of strategies. Some of the parameters are only available for certain strategies and may not be visible in other strategies.

Parameter rules are automatically checked. If a violation occurs, the error indicator  is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

is displayed beside the incorrect parameters. Select the error indicator to display more information about the error.

Switching between strategies can result in the error indicator being shown. This indicates that the chosen combination is invalid, and needs to be corrected.

For more information about the STwrench, see the STwrench User Guide (printed matter number 9836 4134 01).

Parameter name | Condition | Description | Default value |

|---|---|---|---|

End cycle time | It is applied when torque goes below the cycle start and gets to the third percentage value set on the STwrench LEDs. | 100 ms |

Pulsing Tool Strategies

The strategy can be selected if the controller software version supports the tightening program. Pulsing tools can achieve a higher torque compared to normal rotating tools.

Pulse Tightening Program

Start

During the start step, the tool rotates in a speed mode without any pulsing.

Parameter name | Description |

|---|---|

Soft start | Enables setting of the tool’s speed, angle and maximum torque to facilitate the bolt entering the thread. Selected by radio buttons. Off: Soft start is turned off. On: Soft start is turned on. |

Speed | Defines the speed during the soft start. |

Time | Defines the Soft start duration. |

Angle | Defines the target angle to turn the spindle for the bolt to enter the thread. |

Torque max | Defines the upper torque limit during the soft start. If Torque max is exceeded, the tightening is considered NOK. |

Rehit detection | Early: Terminates the tightening immediately when an already tightened screw/bolt is detected. The tightening will be considered as NOK. Requires that Soft start is activated. Complete: Even though an already tightened screw/bolt is detected, the tightening is not terminated until all tightening steps have been executed. The tightening will be considered as NOK. To make a rehit detection when Soft start is not activated, the Rehit detection Complete option must be selected. Rehit detection Complete will not terminate the tightening until all tightening steps have been executed. The tightening will be considered a rehit if the speed fails to reach half the rundown speed, a rehit error is then indicated. Off: No rehit detection will be performed. Combination Soft start = Off and Rehit = Early is not allowed. |

Positive | The TrueAngle compensation can detect tool rotation and make angle compensations within the set limits. |

Negative | The TrueAngle compensation can detect tool rotation and make angle compensations within the set limits. |

Use attachment tuning | Attachment tuning is selected by radio buttons. |

Gear ratio | Socket rotation speed = Tool speed / gear ratio. |

Efficiency tuning | For example 0.9 means 10% efficiency loss. |

Rundown

During rundown, the tool can use either speed mode, with a constant motor speed, or pulse mode. The selection is made depending on the encountered torque and the given torque limits within the configuration.

Parameter name | Description |

|---|---|

High-speed rundown | The rundown step can be done in high-speed in order to minimize the time, without overshooting. This is achieved by letting the tool run at a higher speed for a specified angle length. When the angle has been reached, the speed will change to the lower speed specified in Rundown speed parameter. Only available for SRB tools. Length: Default 3600°, max 99999° Speed: Tool max speed must be higher than Rundown speed (rpm). |

Rundown speed | Rundown speed can be set to either Max or Manual. If Rundown speed is set to Manual; enter the tool speed in rpm. |

Rundown angle limits | Off: Rundown angle limits is turned off. From Trigger: Rundown angle limits is turned On. The system starts to monitor the tightening angle as soon as the tool trigger is pressed and reports if angle limits are violated. From torque: Rundown angle limits is turned On. The system starts to monitor the tightening angle from the specified torque value and reports if angle limits are violated. |

Rundown angle monitoring torque | Torque value from where Rundown angle limits are set. |

Angle min | Angle value for lower angle limit from starting point. |

Angle max | Angle value for upper angle limit from starting point. |

Time min | Minimum time for the step. |

Time max | Maximum time for the step. |

Rundown pulse limits | Selected from a shortcut menu: Off: Rundown pulse limits is turned off. From Trigger: Rundown pulse limits is turned On. The system starts to monitor the pulses as soon as the tool trigger is pressed and reports if the pulse limits are violated. From torque: Rundown pulse limits is turned On. The system starts to monitor the pulses from the specified torque value and reports if the pulse limits are violated. |

Rundown pulse monitoring torque | Torque value from where the Rundown pulse limits monitor starts. The value must be set to a value greater than Continuous max torque. |

Pulses min | Minimum number of pulses to reach the Rundown complete torque value. |

Pulses max | Maximum number of pulses to reach the Rundown complete torque value. |

Rundown complete torque | Defines the torque value for when snug is reached and the rundown is completed. The program proceeds with the tightening and starts with pulse mode, if not already done so during rundown. |

Tightening

Parameter name | Description |

|---|---|

Target torque | Final target torque for the tightening. |

Pulse Energy | The Pulse energy delivered in the action pulse expressed in a percentage of the maximum energy that the tool can deliver in each pulse. |

Reaction force tuning factor | The energy delivered by the tool expressed in a percentage value. The reaction force tuning factor is based on the action energy and results in a comfortable reaction. |

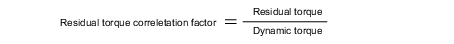

Residual torque correlation factor | The term Residual torque correlation factor is similar to a calibration and adjusts between the dynamic torque, measured in the electrical tool, and the residual torque, measured by a control tool. |

Torque limits | Limits can be Automatically or Manually selected. |

Torque min | Minimum torque for the step. |

Torque max | Maximum torque for the step. |

Angle limits | Off:Angle limits is turned off. From Rundown complete: Angle limits is turned On. The system starts to monitor the tightening angle as soon as Rundown complete is reached and reports if angle limits are violated. From torque: Rundown angle limits is turned On. The system starts to monitor the tightening angle from the specified torque value and reports if angle limits are violated. |

Rundown angle monitoring torque | Torque value from where Rundown angle limits monitoring starts. |

Angle min | Angle value for lower angle limit from the starting point. |

Angle max | Angle value for the upper angle limit from starting point. |

Time min | Minimum time for the step. |

Time max | Maximum time for the step. |

Pulse limits | Off: No pulse limit monitoring. From rundown complete: The monitoring starts when the Rundown complete torque is reached. From torque: The monitoring starts when the specific torque value is reached. |

Final pulse monitoring torque | Torque value from when the pulse limits are monitored. |

Pulses min | Minimum number of pulses to reach the final target. |

Pulses max | Maximum number of pulses to reach the final target. |

Premature torque loss detection time | A constant increase in torque is assumed when moving from rundown to tightening. A socket slip off, or a broken screw head can cause the torque to decrease. This may be detected in a monitoring window. |

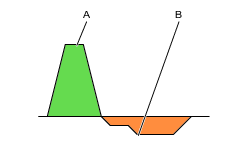

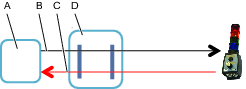

Pulse Tightening with Direct Driven Electrical Tools

The principle below is applicable for direct driven electrical tools. It is applicable to the Atlas Copco SRB series of tools.

The pulse tightening uses a technique of pulsing the electrical current in the motor and has two distinct features:

An action current that adds positive torque in the tightening direction.

A reaction current that creates a comfort reaction by applying a reverse torque.

A | Action pulse to apply tightening force. |

B | Reaction pulse for comfort |

The figure shows the general principle of a current pulse tightening strategy. The detailed curve depends on the tool type and the tightening algorithm.

The pulse period consists of two phases as shown in the figure with an action current and a reaction current. Each action pulse adds torque to the tightening until the final target is reached. Each reaction pulse creates a counterforce that provides a comfortable reaction.

The energy level of the action phase and the reaction phase are configurable parameters. The combination of these two parameters creates an efficient tightening combined with operator comfort.

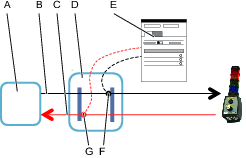

Tightening using the TensorPulse Program

The principle below is applicable for direct driven electrical tool. It is applicable to the Atlas Copco SRB series of tools.

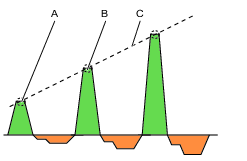

After each pulse period the resulting torque in the screw is increased. After a series of pulses, the final torque target is reached.

A | Maximum positive energy in pulse N |

B | Maximum positive energy in pulse N+1 |

C | Increase in energy (torque) |

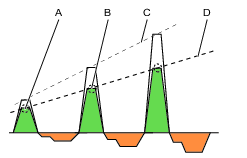

The energy level in the action phase and reaction phase are user configurable parameters. The combination of these two parameters creates an efficient tightening combined with operator comfort. It is possible to set the amount of energy in the two phases as a percentage of the maximum energy that can be delivered in each period:

Pulse energy; The amount of energy that is applied to each positive pulse as a percentage of the maximum energy that can be applied in the pulse period. The value is between 10-100%.

Reaction force retention factor; The amount of energy that is applied to each reactive pulse as a percentage of the maximum energy that can be applied in the pulse period. The value is between 0-75%.

A | Reduced positive energy in pulse N |

B | Reduced positive energy in pulse N+1 |

C | Resulting curve for torque build up using maximum pulse energy. |

D | Resulting curve for torque build up using reduced pulse energy. |

A small Pulse energy (reduced energy) requires more pulses to reach the target torque as the torque is increased in smaller steps. Smaller steps provides better accuracy to terminate the tightening when the target is reached. Smaller pulses decrease tool movement and increases operator comfort.

A correctly tuned Reaction force retention factor will create the desired operator comfort. If the factor is too high the operator feels a clockwise rotation of the tool. If the factor is too low, the operator feels a counter clockwise rotation of the tool.

In an ideal configuration, the reaction energy does not create any loosening force. If the amount of pulses to reach the target value increases, the value is set too high and a small loosening occurs at each pulse.

The optimum values for the Pulse energy and the Reaction force retention factor need to be tuned for optimum performance of the tool and for best operator comfort.

Impulse Single Step Tightening Program

Rundown

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Rundown speed | Selected by radio buttons. Rundown speed can be selected between Max or Manual. | Max | |

Rundown speed | Rundown speed = manual | Specifies the tool speed during the rundown step. | |

Rundown time limits | Selected from a shortcut menu: Off:Rundown time limits is turned off. From Trigger: Rundown time limits is turned On. The system starts to monitor the time as soon as the tool trigger is pressed and reports if the time limits are violated. From torque: Rundown time limits is turned On. The system starts to monitor the time from the specified torque value and reports if the time limits are violated. | Off | |

Rundown time monitoring torque | Rundown time limits = from torque | Torque value from where Rundown time limits monitor starts. | |

Time min | Rundown time limits = On | Minimum allowed time for rundown. | 10ms |

Time max | Rundown time limits = On | Maximum allowed time for rundown. | 5000ms |

Rundown pulse limits | Selected from a shortcut menu: Off:Rundown pulse limits is turned off. From Trigger: Rundown pulse limits is turned On. The system starts to monitor the pulses as soon as the tool trigger is pressed and reports if the pulse limits are violated. From torque: Rundown pulse limits is turned On. The system starts to monitor the pulses from the specified torque value and reports if the pulse limits are violated. | Off | |

Rundown pulse monitoring torque | Rundown pulse limits = from torque | Torque value from where the Rundown pulse limits monitor starts. | 2.5Nm |

Pulses min | Rundown pulse limits = On | Minimum number of pulses to reach the target. | 2 |

Pulses max | Rundown pulse limits = On | Maximum number of pulses to reach the target. | 50 |

Rundown complete torque |

| Defines the torque value for when snug is reached and rundown is completed. | 5Nm |

Tightening

Parameter name | Condition | Description | Default value |

|---|---|---|---|

Target torque | Final target torque for the tightening. | ||

Pulse Energy | The Pulse energy delivered in the action pulse expressed in a percentage of the maximum energy the tool can deliver in each pulse. | ||

Residual torque correlation factor | The term Residual torque correlation factor is similar to a calibration and adjusts between the dynamic torque, measured in the electrical tool, and the residual torque, measured by a control tool. | 100% | |

Torque limits | Selected by radio buttons. Limits can be Automatically or Manually selected | ||

Torque min | Torque limits = manual | Minimum torque for the step. | |

Torque max | Torque limits = manual | Maximum torque for the step. | |

Time limits | Selected from a shortcut menu: Off:Time limits is turned off. From rundown complete: Time limits is turned On. The system starts to monitor the time as soon as rundown complete is reached and reports if the time limits are violated. From torque: Time limits is turned On. The system starts to monitor the time from the specified torque value and reports if the time limits are violated. | Off | |

Time monitoring torque | Time limits = from torque | Torque value from where the Time limits monitor starts. | |

Time min | Time limits = On | Minimum allowed time for tightening. | 10ms |

Time max | Time limits = On | Maximum allowed time for tightening. | 1000ms |

Pulse limits | Selected from a shortcut menu: Off: No pulse limit monitoring. From rundown complete: The monitoring starts when the Rundown complete torque is reached and reports if the number of pulses is outside the limit. From torque: The monitoring starts when the specific torque value is reached and reports if the number of pulses is outside the limit. | Off | |

Final pulse monitoring torque | Pulse limits = from torque | Torque value from when the pulse limits are monitored. | |

Pulses min | Pulse limits = on | Minimum number of pulses to reach the final target. | 2 |

Pulses max | Pulse limits = on | Maximum number of pulses to reach the final target. | 50 |

Premature torque loss detection time | A constant increase in torque is assumed when moving from rundown to tightening. A socket slip of, or a broken screw head can cause the torque decrease. This may be detected in a monitoring window. | 200 ms |

Rotate

The Rotate strategy is primarily a strategy for testing and demonstration purposes. When the tool is allowed to rotate freely, it turns the socket the specified angle using the lowest torque possible.

Parameter | Description | Default value |

|---|---|---|

Target speed | Target speed for the Rotate strategy. |

|

<Target speed> | Manual tool speed during the Rotate strategy. | 16.5% of Tool max speed |

Target angle | Angle to turn the spindle. | 360° |

External Result

External result is a strategy used when an OK tightening is indicated by an external digital signal (and not by torque or angle values measured during tightening).

When the signal is sent, the Result view will show the value of the Target parameter provided in the tightening program (specified torque value, angle value, or text string). These (torque and angle) values do not represent actual measured values, but only inserted text.

Parameter | Description | Default value |

|---|---|---|

Torque <Target torque> | Numerical value for desired displayed target torque value | 0.00 |

Angle <Target angle> | Numerical value for desired displayed target angle value | 360° |

Text | Alphanumerical string for desired displayed text. |

|

Running the External Result Tightening Strategy with a Tool Connected

On the Home view, select the Tightening Tab. Then, create a tightening program with External Result strategy.

Return to the Home view and select the Virtual Station Tab.

In the Licenses window, the External Result Tightening Strategy with a Tool Connected feature requires a license to be assigned and used by a virtual station.

In the Tool window, select the necessary tool. Then, select the tool configuration.

In the Task window, select the tightening program with an External Result strategy.

Send EXTERNAL_OK signal to the Virtual Station.

Select Go Result button to display the results.

Results are sent from the Tool configuration for the tool connected to the Virtual Station.

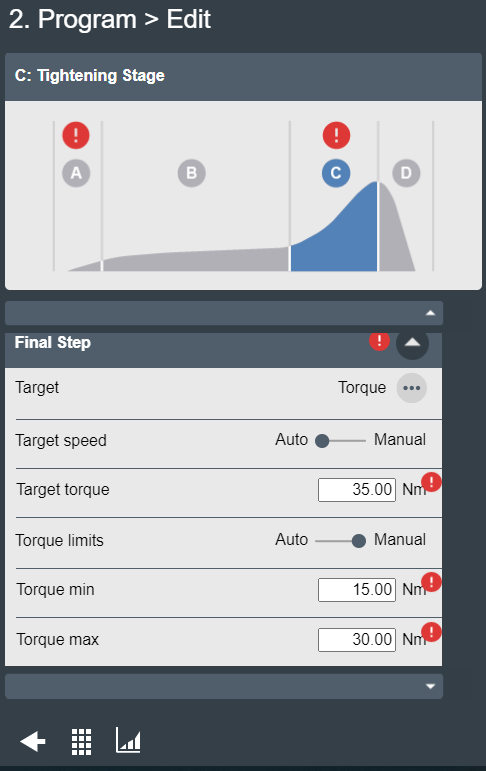

Tightening Program and Error Reporting Validation

The tightening program automatically validates with the parameter rules and tool properties as soon as new values are entered or changes are made. If the validation detects any errors they are reported with an error description.

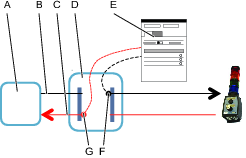

Validation Error Reporting

If the validation gives an error, it is displayed with an icon next to the parameter or parameters causing the error. When you tap on the icon, a short description of the error is given.

Example (See image):

Target torque is set to 25 Nm with Final torque limits set to Torque min 23.75 Nm and Torque max 24.5 Nm (this value is hidden by the pop-up window in the image).

When you tap on the validation error icon next to the Torque max parameter, a short description of the error is given, saying that Target torque is greater than Torque max (Torque max <= Target torque).

To fix the error, adjust the Torque max value so that it is greater than Target torque, and the error icon will disappear.

Validate a Tool with a Tightening Program

In the Tightening menu, choose Tightening program library or Multistep program library. If required, select a specific program in the list. Note that validation can be performed both for the entire list of programs, or for individual programs.

Select the validate program icon in the upper-right corner of the screen.

In the pop-up window, choose the tool to validate the tightening program against, and select Validate.

If a tightening program is not compatible with the selected tool, it will be indicated by a red circle with an exclamation point.

Tightening Program Tool Compatibility Table

The availability of tightening strategies depends on the licenses installed on the controller.

Tightening Strategies | ES | ST | STR | SR | SB+ | ETT | SL (low voltage) | QST | STB | SRB 2.0 ETP-SRB31-20 | SRB 2.1 ETP-SRB31-25 | SRB-HA | TBP / TBP-S | STW | External tool |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Two step | X | X | X | X | X | X | X | X | X | X | - | X | - | - | - |

Quick step | X | X | X | X | X | X | X | X | X | X | X | X | - | - | - |

Three step | X | X | X | X | X | X | X | X | X | X | - | X | - | - | - |

Turbo Tight | X | - | X | X* | - | X | - | - | - | X | X | - | - | - | - |

Rotate | X | X | X | X | X | X | X | X | X | X | - | X | - | - | - |

External Result | X | X | X | X | X | X | X | X | X | X | X | X | X | - | X |

Tensor Pulse | - | - | - | - | - | - | - | - | - | X | X | - | - | - | - |

Impulse - single step | - | - | - | - | - | - | - | - | - | - | - | - | X | - | - |

Wrench production | - | - | - | - | - | - | - | - | - | - | - | - | - | X | - |

Wrench quality | - | - | - | - | - | - | - | - | - | - | - | - | - | X | - |

* Available only for SR31.

Tightening Features | ES | ST | STR | SR | SB+ | ETT | SL (low voltage) | QST | STB | SRB 2.0 ETP-SRB31-20 | SRB 2.1 ETP-SRB31-25 | TBP / TBP-S | STW | External tool |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

True Angle | - | - | X | - | - | X | - | - | - | - | - | - | - | - |

Multistep Programs

Controller features, such as the Low Reaction Tightening Strategies and controller-wide functions among others, require licenses distributed through the Functionality Management System (FMS). Whereas configuration of features is possible without specific licenses, the assignment and use of those features will require the correct license to be installed on the controller. Please refer to Licenses (FMS) for more detailed information on licenses.

A multistep tightening is a tightening done in several steps. The number of steps and the type of steps vary depending on the tightening to be done. A multistep tightening program is highly configurable, including monitoring function and restrictions.

Multistep GUI Interface

Multistep tightening programs can only be edited in the web GUI.

The interface for mutistep programs can be divided into three main areas.

On top there is a drop-down menu containing the Properties of the multistep tightening program. Here general properties such as program name, overal program monitor and validation can be filled out.

To the right there are four tabs containing the steps, monitors, restrictions and reporters that can be used to build the multistep program. To use any of the items, click on the appropriate tab, and drag the item in the list to the tightening area. Depending on its funtion, either drop the item between the beginning and the end of the program (for steps), or on top of a particular step (for monitors and restrictions).

The main area of the interface is the tightening area. This is the area that includes all the steps in the tightening program. Scroll the mouse wheel to zoom in and out on the tightening area.

At bottom left of the screen there is a Copy Tightening Program button and a Delete Tightening Program button.

Tightening Steps

The availability of tightening steps, monitors and restrictions depends on the license installed on the controller.

General Parameters

The following step parameters are common for many of the step types. The parameters are set in the step properties window which is displayed when selecting a step in the tightening program.

Parameter | Description |

|---|---|

Name | Name of the step. |

Rotational direction | Each of the tightening steps can run either forward, that is to make a tightening, or reverse, to loosen the screw slightly. The arrows indicate this direction. Many of the tightening steps have a direction hard-coded to forward, for example Tighten to Angle, or Tighten to Torque. Steps such as Loosen to Angle or Loosen to Torque have their direction automatically set to reverse. The reverse setting is not allowed for tools configured with Gear Front Attachment (GFA) of type open end. The tightening direction of the tightening program must be the same as the tightening direction of the open end tool for a tightening to be allowed to be run. It is possible to assign a loosening program to a tightening program for an open end tool, but if the direction switch is set to run the loosening program, the tool will be locked. |

Step category | For each step, there is an option to choose a step category. By selecting step category, the NOK tightenings will be listed in the event result view with related detailed status together with the corresponding multistep error information. If no selection is made, the detailed status will be set to "uncategorized multistep error". The related detailed status can be customized. |

Angle window | A joint is considered Hard if the screw is tightened to its full torque and it rotates 30 degrees (or less) after it has been tightened to its snug point. A Soft joint rotates 720 degrees or more after it has been tightened to its snug point. The hardness parameter defines the Angle Window for the gradient calculation. The harder the joint - the smaller the angle window. |

Speed Ramp / Acceleration (only available in ToolsTalk 2) | For most of the steps it is possible to specify how the acceleration to the target speed should be achieved. Three different settings are possible; Hard, Soft and Manual. The acceleration defined will be used whenever a step is started. Regardless whether the tool is already running with speed at the beginning of the step, the ramp will be used to accelerate to the target speed of the step. This will be the case even if the speed at the start of the step is higher, or lower than the target speed. |

Speed ramp - Hard and Soft mode |

|

Speed ramp - Manual mode |

|

Using speed shifts | 1−5 angle triggers or torque triggers can be defined during a step, where the speed will shift. Within one step, all the speed shift triggers are based on the same property, that is either torque or angle. They cannot be mixed within one step. The Torque triggers and Angle triggers must be less than the step target, depending on the type of the step and the trigger type. The Torque trigger and Torque speed also validate against the Max torque and Max speed of the tool. A warning or error indicator occurs whenever the Speed Shift settings exceed either the tool max values, or step max values. The Torque triggers and Angle triggers must be less than the step target, depending on the type of the step and the trigger type. The Torque trigger and Torque speed also validate against the Max torque and Max speed of the tool. A warning or error indicator occurs whenever the Speed Shift settings exceed either the tool max values, or step max values. It is possible to push the settings to the tool when a tightening program has a warning, but not when a tightening program has an error (fault) indicator. The speed shifts can be added in the Configuration field. To add a speed shift: In the dialog box of a step that can have speed shifts, select Add speed shift. Then, select an angle range or a torque range.

|

Brake type | The braking behavior of a multistep tightening program can be controlled at two possible locations in the program: in a step preceding a reversal of direction of the tightening, and/or at the final step of the tightening program. At other locations in the tightening program, the braking parameters will not be available in the step's general settings. Braking can be set to either Ergo stop or Inertia. Inertia will brake the tool completely, while Ergo stop will allow for a more ergonomic slowing down of the tightening. Inertia has no additional parameters. Ergo stop parameters:

|

The following tightening steps are not supported for tools configured with Gear Front Attachment (GFA) of type open end:

A - Tighten to Angle / Loosen to Angle

TrR - Loosen to Trigger Release

T - Tighten to Torque / Loosen to Torque

E - Engage

SR - Socket Release

DT - Tighten to DynaTork

TP - TensorPulse

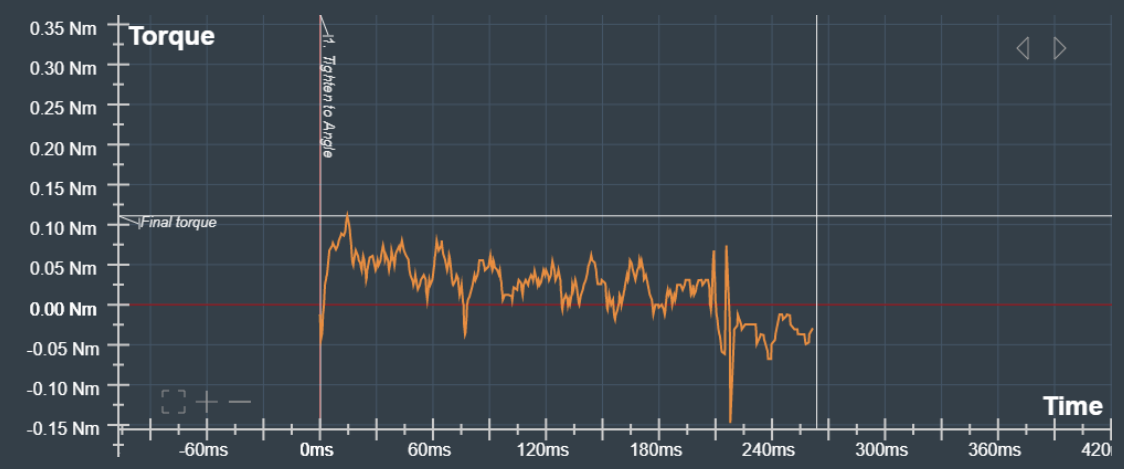

Trace Settings

When the trace configuration is enabled on the program level, the trace resolution can be configured on step level. The setting for Trace Setting defines how the sampling should be done on each specific step.

Parameter | Description |

|---|---|

Trace Setting |

|

Sample Time | Choose the sample time from the drop-down list (0.25 - 1000 ms) |

Sample Angle | Choose the sample angle from the drop-down list (0.25 - 20 degree) |

With this trace recording the sample rates will not be the same in all the steps, instead the sample rate depends on the configuration in each step. This means the trace is divided into one trace for each step.

The maximum number of samples in a trace is 4096.

If a tightening produce more than 4096 values a down-sampling will take place. This is done by removing every second trace sample from the whole tightening and when continue the recording with half the resolution. This process will be repeated every time the 4096 sample limit is reached.

If more than 2048 in total was recorded, this process will result in a trace between 2048 and 4096 samples.

If the limit if 4096 samples is reached the configured trace sample times will no longer be followed. Instead the sample times will be doubled or quadrupled etc., depending on how many times the down sampling has taken place. Since all steps are down sampled the relation between the steps will still be the same though. If a step was configured with double sample time compared to another step, this will still be the case in the final trace regardless how many times a down-sampling has occurred.

If more than 4096 samples is recorded, the configured trace sample times will no longer be followed. Instead the sample times will be doubled or quadrupled, etc., depending on how many times the down sampling has taken place. Since all steps are down sampled the relation between the steps will still be the same though. If a step was configured with double sample time compared to another step, this will still be the case in the final trace regardless how many times a down-sampling has occurred.

Trace channel | Note |

|---|---|

Torque | Available for all tools equipped with a torque transducer |

Angle | Available for all tools |

Torque Second | Only available for tools with two torque transducers |

Angle Second | Only available for tools with two angle transducers |

Current | Available for all tools |

Gradient | Available if some step/restriction/monitor produces the gradient values |

Power Focus 6000 / Power Focus 8 | Power Focus 6000 StepSync / Power Focus 8 StepSync | Flex | IxB |

|---|---|---|---|

ST | ST | QST | IxB |

STR | STR | ||

SL | QST | ||

QST | |||

STB | |||

IxB | |||

Power Focus Connect |

A – Tighten to Angle / Loosen to Angle

Tools |

|---|

ES STR SL ST SR QST STB IXB |

A – Tighten to Angle

This step runs the tool until the target angle is reached. The target angle is measured from the start of the step.

A – Loosen to Angle

This step runs the tool with the speed n in the backward direction until the angle target is reached. The target angle is measured from the start of the step.

This step is not supported for tools configured with Gear Front Attachment (GFA) of type open end.

Parameters

Parameter | Description |

|---|---|

Target angle | The angle target. Must be > 0. |

Speed | Default: 60 rpm. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Brake (Valid only for Power Focus 6000 StepSync, Power Focus 8 StepSync, and Flex). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

A | Target Angle |

Microvideo

C - Clutch

Tools |

|---|

BCV BCP |

This step will run the tool with the programmed Speed in forward direction until the Clutch has been released. When the tool has reported the release of the Clutch the step will finish with OK status.

A tightening program using the Clutch step cannot have any other step assigned.

This step is only valid for the Clutch tools BCV-RE and BCP-RE.

Parameter | Description |

|---|---|

Speed Control | One Speed or Two Speed |

Final Speed | Sets the final speed of the program [rpm] |

Speed Ramp | Switch where speed ramp can be chosen [Hard, Soft] |

Rehit | Rehit detection set to On or Off |

Rehit angle | Sets the rehit angle [°] |

CL - Clutch Loosening

Tools |

|---|

BCV BCP |

This step will run the tool with the programmed speed in reverse direction until the tool trigger is released.

A loosening program using the Clutch step can not have any other step assigned.

This step is only valid for the Clutch tools BCV-RE and BCP-RE.

Parameter | Description |

|---|---|

Final | Sets the speed of the program [rpm] |

DI – Run Until Digital Input

Tools |

|---|

ES STR SL ST SR QST |

This steps runs the tool, in the direction defined by parameter Direction, until the input specified by Digital Input goes high or low depending on the value of Stop Condition.

Parameter | Description |

|---|---|

Direction | Forward, or Backward |

Digital Input | One of the following local digital inputs on the controller can be selected:

|

Brake (Valid only for Power Focus 6000 StepSync, Power Focus 8 StepSync, and Flex). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

Stop Condition |

|

Speed (rpm) | Default: 60 rpm. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | Available if Speed ramp type is Manual. Default: 500 rpm/s. |

Microvideo

DT – Tighten to DynaTork

Tools |

|---|

ES STR SL ST SR QST STB |

This step is not supported for tools configured with Gear Front Attachment (GFA) of type open end.

This step runs the tool with speed n in the forward direction until the Target torque is reached. The tool will then hold the current constant at the DynaTork Percentage of Target torque during the DynaTork time.

To avoid overheating of the tool, it is strongly recommended to never run DynaTork to more than 40% of the maximum torque of the tool.

Parameter | Description |

|---|---|

Target torque | The torque target. Must be > 0. |

DynaTork Time | The time DynaTork will be active. |

DynaTork Percentage | The percentage of Torque target. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Speed (rpm) | Default: 60 rpm. |

Brake (Valid only for Power Focus 6000 StepSync, Power Focus 8 StepSync, and Flex). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

A | Target Torque |

B | Torque level retained during DynaTork Time |

C | Percentage of Ts |

D | Percentage of Ts |

E | Torque level retained during DynaTork Time |

F | DynaTork Time |

Microvideo

E - Engage

Tools |

|---|

ES STR SL ST SR QST IXB |

This step is not supported for tools configured with Gear Front Attachment (GFA) of type open end.

This step runs the tool in both directions until the socket engages the screw. The step continues until Target torque or Target angle is reached, provided that Continue if not Engaged is set to Yes. If Target Angle is reached in any direction, the direction is reversed. Limit the search iterations by entering Max Engage Attempts. If Target Torque is reached in any direction the step will finish with OK status.

Microvideo

Ext - External Result

Tools |

|---|

ES STR SL ST SR QST STB IXB BCP BCV External Tool |

External result is a strategy used when an OK tightening is indicated by an external digital signal (and not by torque or angle values measured during tightening). This external signal can be provided through any means that can provide a digital signal into the controller (e.g through the I/O bus).

When the signal is sent, the result view (logged data) will show the value of the Target parameter provided in the tightening program (specified torque value, angle value, or text string). These (torque and angle) values do not represent actual measured values, but only inserted text.

Parameter | Description |

|---|---|

Torque <Target torque> | Numerical value for desired displayed target torque value. A signal could for example come from a Click Wrench and display <Target torque>. |

Angle <Target angle> | Numerical value for desired displayed target angle value. A signal could for example come from a Click Wrench and display <Target angle>. |

Text | Alphanumerical string for desired displayed text. For example: "Oil has been changed". |

MWR - Mechatronic Wrench

Tools |

|---|

MWR |

Mechatronic Wrench is a specialized step that can be used only in conjunction with the Mechatronic Wrench (MWR).

This step cannot be used in combination with other steps. No restrictions can be used with this step. By default, the step has three monitors: Peak Torque, Angle, and Click.

Parameter | Description |

|---|---|

Loosening limit | Numerical value for negative torque (i.e. torque in the loosening direction) at which point the tightening result is marked as NOK (False direction of tightening (loosen)); in Nm. |

Tool Size | Numerical value for the specific length of the end fitting tool installed on the MWR-TA; in mm. |

Tool Bend | Numerical value for the end fitting tool installed on the MWR-TA; in °/Nm. |

Rehit Angle Window | Numerical value for the angle for determining if the screw was already tightened if the torque is reached; in °. |