QST50-150CT-T50-L137-H13

Electric straight nutrunner

Product information

General information

Safety signal words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

|

DANGER |

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

|

WARNING |

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

|

CAUTION |

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

|

NOTICE |

NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12 months after the product is first taken into use, but will in any case expire at the latest 13 months after delivery.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

Website

Log in to Atlas Copco: www.atlascopco.com.

You can find information concerning our products, accessories, spare parts and published matters on our website.

ServAid

ServAid is a portal that contains technical information for all hardware and software products such as:

- Safety Information including declarations, standards and directives

- Technical data

- Installation, Operation and Service Instructions

- Spare parts lists

- Accessories

ServAid is continuously updated and is available at:

https://servaid.atlascopco.com

For further information contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The safety data sheets describes chemical products sold by Atlas Copco.

For more information, consult the website:

www.atlascopco.com/sds

Country of origin

Please refer to the information on the product label.

Dimensional drawings

For information about the dimensions of a product, see the Dimensional drawings archive:

http://webbox.atlascopco.com/webbox/dimdrw

Overview

Technical data for QST Nutrunners

Ordering No | 8435605010 |

Model | QST50-150CT-T50-L137-H13 |

Gear ratio | 31.24 |

Min C-C | 51 |

Socket holder size | 1/2 in |

Sound power | dB(A) |

Sound pressure | <70 dB(A) |

Sound standard | ISO15744 |

Sound uncertainty | dB(A) |

Speed | 380 r/min |

Torque range | 30–150 Nm |

Torque range | 22–110 ft lb |

Travel | 50 mm |

Weight | 5.8 kg, 12.8 lb |

A | 137mm |

B | 23mm |

C | 464mm |

D | 15mm |

E | mm |

CT - Straight Nutrunner

COT - Offset Nutrunner

CTV - Angle head Nutrunner

Service overview

Service recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

-

Clean appropriate parts accurately

-

Replace any defective or worn parts

Installation

Installation requirements

Clamping

No clamping is allowed on the transducer, the gear unit or the motor unit. Clamping on these areas will interfere with the transducer.

Compression spring

The QST nutrunners are delivered with two springs. The strong spring is built in the front part.

Motor connector

The motor connector is rotatable ± 150 degrees along two axes.

Service

Preventing ESD problems

The components inside the tool and controller are sensitive to electrostatic discharge. To avoid future malfunction, make sure that service and maintenance is carried out in an ESD approved work environment. The figure below shows an example of an appropriate service work station.

Maintenance instructions

Service recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

-

Clean appropriate parts accurately

-

Replace any defective or worn parts

Recycling

Recycling instruction

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

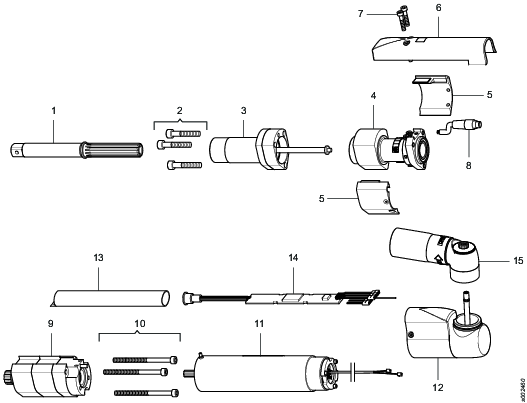

Recycling information for QST (34-150Nm)

Part: | Recycle as: | |

|---|---|---|

1 | Socket holder | Metal, Steel |

2 | 3 screws | Metal, Steel |

3 | Front part | Metal, Steel |

4 | Transducer | Metal, Steel |

5 | 2 Covers | Metal, Aluminum |

6 | Cable rail | Metal, Zink |

7 | 2 Screws | Metal, Steel |

8 | Cable | Electronic |

9 | Gear unit | Metal, Steel |

10 | 3 Hex socket screws | Metal, Steel |

11 | Motor | Electronic |

12 | Motor (back part) | Metal, Aluminum |

13 | Communication card tube | Metal, Stainless steel |

14 | Communication card | Electronic |

15 | Connector | Electronic |