Power Supply Unit 950

Power supply

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12+1 months after dispatch from Atlas Copco's Distribution Center.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

System Functionality

1 | Power Cable |

2 | Power Supply Unit |

3 | Adapter Cable |

4 | Tool |

For power intense applications the PSU might not be able to supply enough power, see Troubleshooting for more information.

When PSU is installed with larger tools, for example ITB-A61 and TBP13, it is always recommended to ensure that the PSU is suitable for the application and verify correct function.

Product Functionality

1 | Power Supply Unit 950W |

2 | Attachment tabs |

3 | Power cable retainer |

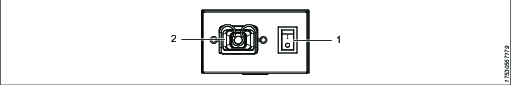

1 | On/off switch button |

2 | Outlet for Power Cable |

1 | Adapter Cable connector |

2 | Power LED |

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

Service Overview

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Replace any defective or worn parts

Installation

Installation Requirements

Mounting Instructions

Make sure the Power Supply Unit is disconnected from the power source before proceeding with the installation.

The Power Supply Unit has to be mounted onto a wall. Use M5 screws and fasten the screws through the attachment tabs.

Installation Instructions

Installation Instructions

Connecting the Power Cable to the Power Supply Unit

Insert the Power Cable into the Power Supply Unit.

Mount the Power Cable retainer to the Power Supply Unit.

Push the Power Cable retainer upwards until it clicks into place underneath the Power Cable.

Connecting the Adapter Cable to the Power Supply Unit

Make sure that the locking mechanism on the Adapter Cable is in open position.

Insert the Adapter Cable into the locking mechanism on the Power Supply Unit.

Twist the locking mechanism into closed position.

Connecting the Adapter Cable to the tool

At the rear of the tool, remove the two screws underneath the tool.

Align the Adapter Cable with the feet of the tool.

Press the front feet on the tool into the front slots on the Adapter Cable.

Slide the front feet on the tool forwards inside the slots.

Press the rear feet on the tool down into the Adapter Cable.

Attach two of the screws provided with the Adapter Cable. Make sure to choose the correct length of the screws.

Required torque = 2Nm

Slide the protective cover over the Adapter Cable into place, so that it covers the bottom plate and the screws.

Connecting IxB tools

For IxB tools, event 2219 “Power source: unknown” will be logged at start-up.

For IxB tools, event 2095 “Tool battery communication lost” will be displayed and logged at start-up, ignore the message, there is no communication between PSU and IxB. Configure event to turn off warning, see instructions in User Guide IxB software.

Connecting the tool to Power Focus 6000

Turn ON the Power Supply Unit.

Pair the tool to the Power Focus 6000, see the Power Focus 6000 User Guide.

Keep The Power Supply Unit always ON while pairing with Power Focus 6000

Service

Preventing ESD Problems

The components inside the product and controller are sensitive to electrostatic discharge. To avoid future malfunction, make sure that service and maintenance is carried out in an ESD approved work environment. The figure below shows an example of an appropriate service work station.

Maintenance Instructions

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Replace any defective or worn parts

Service

Troubleshooting

Troubleshooting

In case of Power Focus generating event 2089 “Tool drive voltage”

Tool is most likely requiring more power than the PSU can supply. This can be caused by demanding applications with target torque close to tool max, soft joints, high tightening speed and running with full pulse energy in combination with a low mains voltage. This can in most cases be prevented by reducing the pulse energy level or tightening speed.

In case of Power Focus or IxB generating event “Drive Error”

Tool is most likely requiring more power than the PSU can supply. This can be caused by demanding applications with target torque close to tool max, high tightening speed or soft joints. This might be prevented by reducing the pulse energy level or tightening speed.

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Instruction

Position | Part | Remark | Recycle as |

|---|---|---|---|

1 | Power Supply Unit 950W | Electronics |

Recycling Instruction

Position | Part | Remark | Recycle as |

|---|---|---|---|

1 | Screw | 2 pcs | Metal, Steel |

2 | Top Part | Plastic, other, PA | |

3 | Terminal | Plastic, other, PC+ABS | |

4 | Nut | Metal, Brass | |

5 | Bottom Part | Plastic, other, PA | |

6 | Protective Cover | Plastic, TPU | |

7 | Over mold Part | Plastic, other, PA12 | |

8 | Cable | Metal, Copper | |

9 | Screw | 2 pcs | Metal, Steel |