Oil Filling and Changing Instruction

Impulse Nutrunner

Instruction Supplement

Atlas Copco Oil Filling Kit Secures Optimal Performance

A correct oil level is crucial for durability and optimal performance of pulse tools over time. A quick and reliable oil filling process is achieved with the Atlas Copco Oil Filling Kit, which is specially designed for EP PTI, EP PTX, and ETP TBP pulse tools.

The benefits of this new design are:

Makes it much easier to achieve the right oil level in the pulse unit

Changing and filling the oil is now a much quicker process

Minimum risk of oil spill

Practically no human exposure to old dirty oil

Oil Filling and Changing Instruction for Pulse Unit on EP PTI, EP PTX, and ETP TBP Tools

Required equipment for oil filling and oil changing:

Atlas Copco Pulse unit oil.

Atlas Copco Pulse unit Oil Filling Kit.

For ordering number for Spare Parts, see https://servaid.atlascopco.com.

Oil Filling Equipment Kit

2 x Adapter M3

2 x Adapter M4

4 x Hose length 540 mm

2 x Hose length 50 mm

1 x Hose length 120 mm

1 x Syringe 50 ml

1 x Syringe 1 ml

4 x Plug

5 x Connection

2 x Connection

2 x Can

2 x Cover

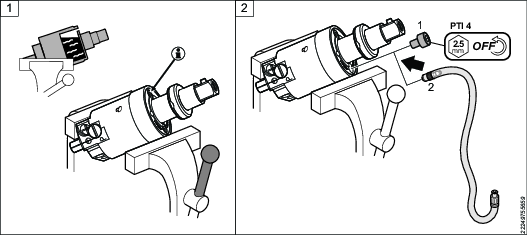

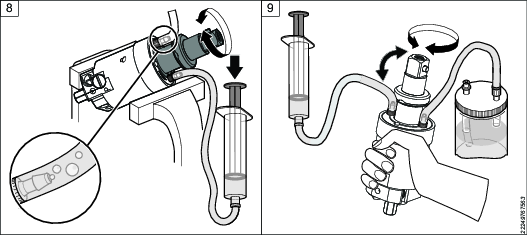

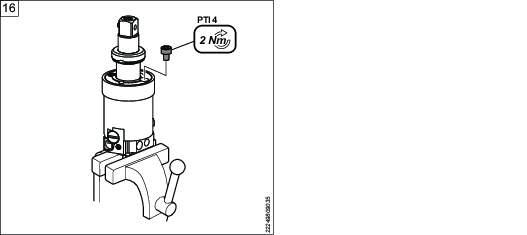

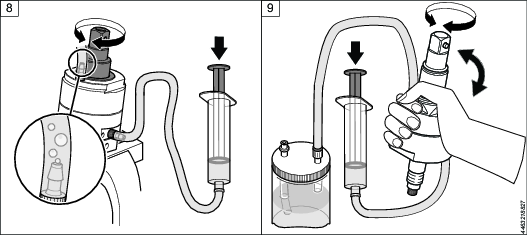

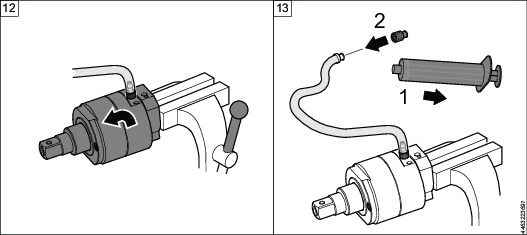

Place the pulse unit in a vise at an angle so that the outlet hole is at the highest point.

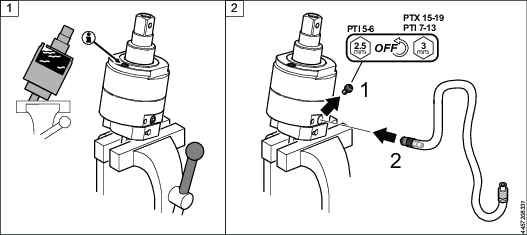

Remove the screw covering the inlet opening. Make sure that the o-ring is on the screw and not left in the pulse unit. Attach the filling hose by hand, with the hose connector end to the pulse unit.

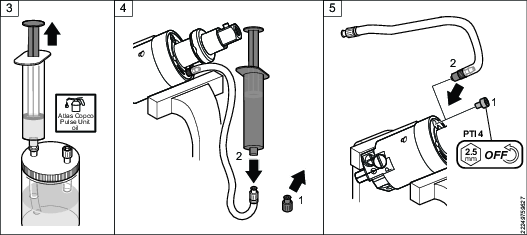

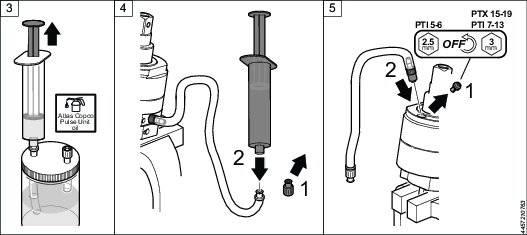

Fill the large syringe with oil to maximum capacity from the oil can.

Always use new Atlas Copco Pulse unit oil.

Remove the stop plug from the filling hose and then attach the syringe to the hose.

Remove the screw covering the outlet opening of the pulse unit. Make sure that the o-ring is on the screw and not left in the pulse unit. Attach the return hose to the pulse unit.

Remove the stop plug from the return hose and then attach it to the oil can.

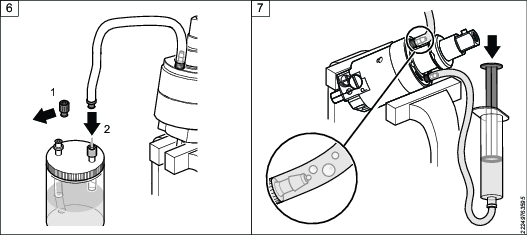

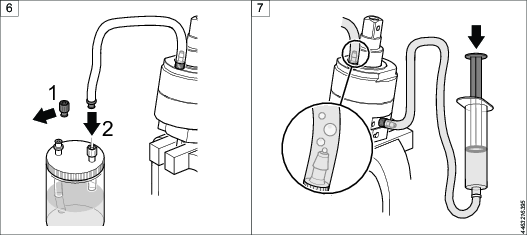

Start filling oil into the pulse unit from the large syringe. When filling oil into the pulse unit, there will be air bubbles exiting.

Rotate the anvil back and forth while filling the oil until no more bubbles are coming out of the Pulse unit.

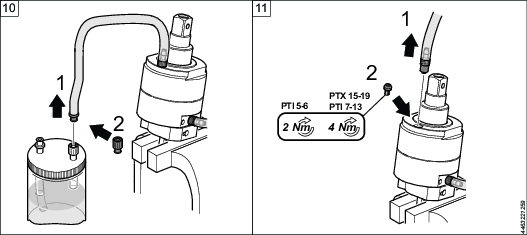

Spin the complete Pulse unit around while filling the oil, to make sure that there are no air bubbles left inside of the Pulse unit.

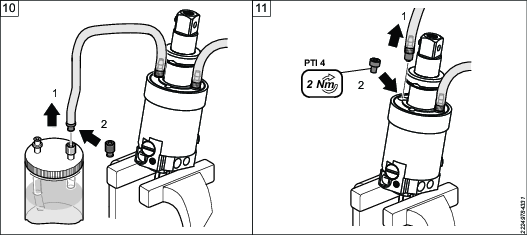

Remove the return hose from the oil can and attach the stop plug to the return hose end.

Remove the return hose from the outlet opening of the pulse unit. Put the screw covering the outlet opening back in position.

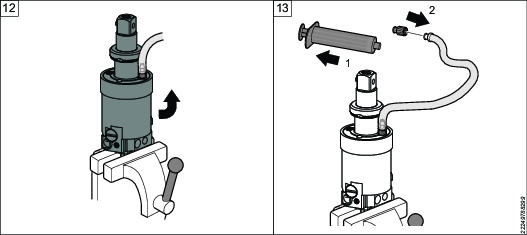

Now position the pulse unit in the vise with the inlet opening facing upwards.

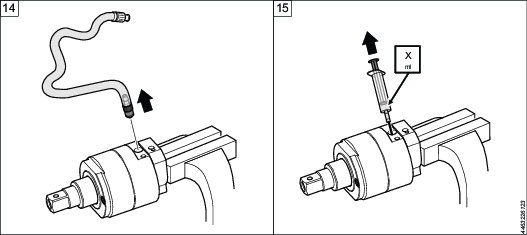

Remove the syringe from the filling hose and attach the stop plug to the filling hose.

Remove the oil filling hose from the pulse unit.

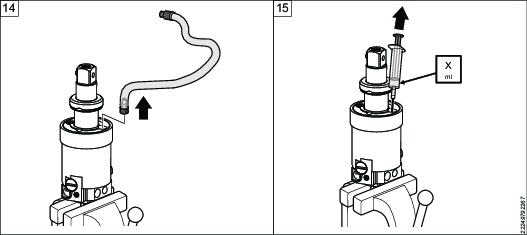

Use the small syringe to extract the right amount of oil according to Product Instructions for your specific tool in ServAid.

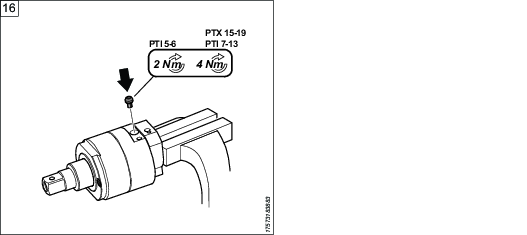

Put the screw covering the inlet opening back in position.

Illustrated Procedure for EP PTI 4 Tools:

Illustrated Procedure for EP PTI 5-6, 15-19, and EP PTX Tools:

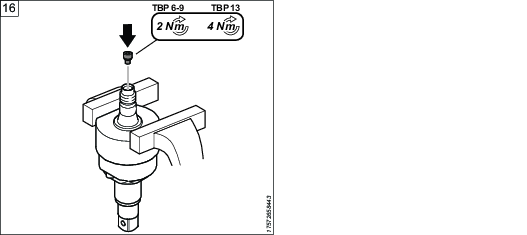

Illustrated Procedure for ETP TBP Tools: