Tool menu

Tool information

The Tool information view contains information used for giving service personnel accurate information about the tool connected to the controller, so that they can give adequate help and support, or for operators to see what tool is connected to the controller.

Parameter | Description |

|---|---|

Model | Tool model denomination. |

Max speed | The maximum rotation speed of the tool. |

Gear ratio | The ratio of the angular velocity of the input gear to the angular velocity of the output gear. |

Serial number | The tool’s serial number may be needed when the correct version of the product instruction is required, in order to get the correct spare parts or service instructions. |

Max torque | The maximum torque the tool can use for a tightening. |

Software version | Tool software version. |

Product number | The tool’s product or ordering number. |

Connection

The Connection pane displays what FlexDrive the tool is connected to.

Health

Parameter | Description |

|---|---|

Tool electronics temperature | Displays electronics temperature. Click to display a list of electronics peak temperature. |

Tool motor temperature | Displays motor temperature. Click to display a list of tool motor peak temperature. |

Maintenance

The tool stores a service interval number and counts how many tightenings can be performed before a tool maintenance or service should be performed.

Parameter | Description |

|---|---|

Last service | Date and time when last service was performed. The Last service date is set at the repair workshop. The Last service date is set to current date and time when the Reset service count button is pressed. |

Total tightenings at service | Total number of tightenings performed by the tool since it was used for the first time. This value is updated at each service, and will remain the same until the next service. |

Remaining tightenings | Total number of tightenings left until the service interval is reached. |

Service interval | Number of tightenings to be performed before the next service. Can be set in multiples of 10 000. |

Reset service counter | Reset of the Remaining tightenings counter and sets Last service date to current date. |

Calibration

Parameter | Description |

|---|---|

Last calibrated | Shows the last time the tool was calibrated. |

Calibration value | Calibration value |

Next calibration date | Set date for next calibration. |

Preparing the calibration

Make sure the tool and controller are set up to perform tightening. Set up the tool with a torque reference transducer such as an STanalyser, ACTA or BLM Bench. Refer to the torque reference transducer’s product information for set-up instructions.

Choose a tightening program with a target torque corresponding to a tightening normally used with your tool.

Calibrating the tool

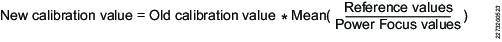

To set the tool’s calibration value, it must first be calculated from the torque readings from the controller and the torque reference transducer by using the equation below.

In the Tool menu, select the tool to calibrate and go to Calibration.

Note the old calibration value in the Calibration value text box.

Make at least three tightenings and use the torque values read from the controller and the reference transducer (ACTA or similar) for calculating the mean torque values.

Calculate the new calibration value.

Store the new calibration value in the tool memory by entering the calculated value in the Calibration value text box and clicking Apply.

Tool diagnostics

To diagnose a tool, the angle or torque sensor, it is possible to start Sensor tracking in the Tool menu. A Sensor tracking session has a time out of 20 minutes. A warning is shown 5 minutes before timeout and it is then possible to extend the session or to stop it.

Sensor tracking is only possible for cable tools.

It is only possible to start one Sensor tracking session for each controller at a time.

Tool angle | How much the tool has turned since the sensor tracking session started or since the last reset. |

Torque | Readout: the instantaneous value for the torque. |

Speed | Readout: the instantaneous value for the speed. |

Start a sensor tracking session

In the HOME window select Tool.

Select Cable Tool and Sensor Tracking in Diagnostics.

Turn On Start sensor tracking.

Tool angle, torque and Speed are shown.

Zero position

This configuration makes a system always return to the original start position for each tightening or sequence. Zero Position is set for each tool separately for both handheld and fixtured. Zero position sets the current position of the tool. It is not possible to set Zero Position during an ongoing tightening or sequence.

Set a zero position:

In the home view select Tool.

Select Cable Tool and then Zero Position in the right menu.

Select SET. The current position of the tool will be set as Zero Position.

Motor tuning

A motor tuning adjusts the tool’s motor control unit to optimize the performance and minimize loss

Always do a motor tuning when a tool is moved from a Power MAC 4000 system to a PF6 FlexSystem.

Starting the motor tuning

The motor tuning will take approximately 1 minute to perform and will rotate the tool in high speed in both clockwise and counterclockwise directions before it is finished.

Open the Tool menu.

In the Motor tuning menu select Perform.

Click Start to start the motor tuning.

Zero offset and shunt

Information | Description |

|---|---|

Shunt value | Maximum allowed measured shunt calibration value in %. |

Shunt drift value | Maximum allowed change in measured shunt calibration value in %. |

Zero offset value | Maximum allowed Zero offset compensation in %. |

Zero offset drift value | Maximum allowed change in the zero offset compensation in %. |

Transducer information

Information | Description |

|---|---|

Enabled | Indicates if the transducer is enabled. |

Gear ratio | The gear ratio between the transducer and the out-going shaft of the tool. |

Wind-up | The wind-up compensation factor for the angle transducer. |

Information | Description |

|---|---|

Enabled | Indicates if the transducer is enabled. |

Serial Number | Serial number of the transducer as a string. |

Article Number | Article number of the transducer as a string. |

Calibration Value | Calibration value for the transducer expressed in Nm. |